Kansai Electric Heat Corp.

Spot Heater (800 °C Specification)

High-Temperature Electric Hot Air Heater

- A high-temperature electric heater capable of delivering hot air up to 800 °C.

- Built with a pressure-resistant heater casing rated at approx. 490 kPa.

Table of Contents - Spot Heater

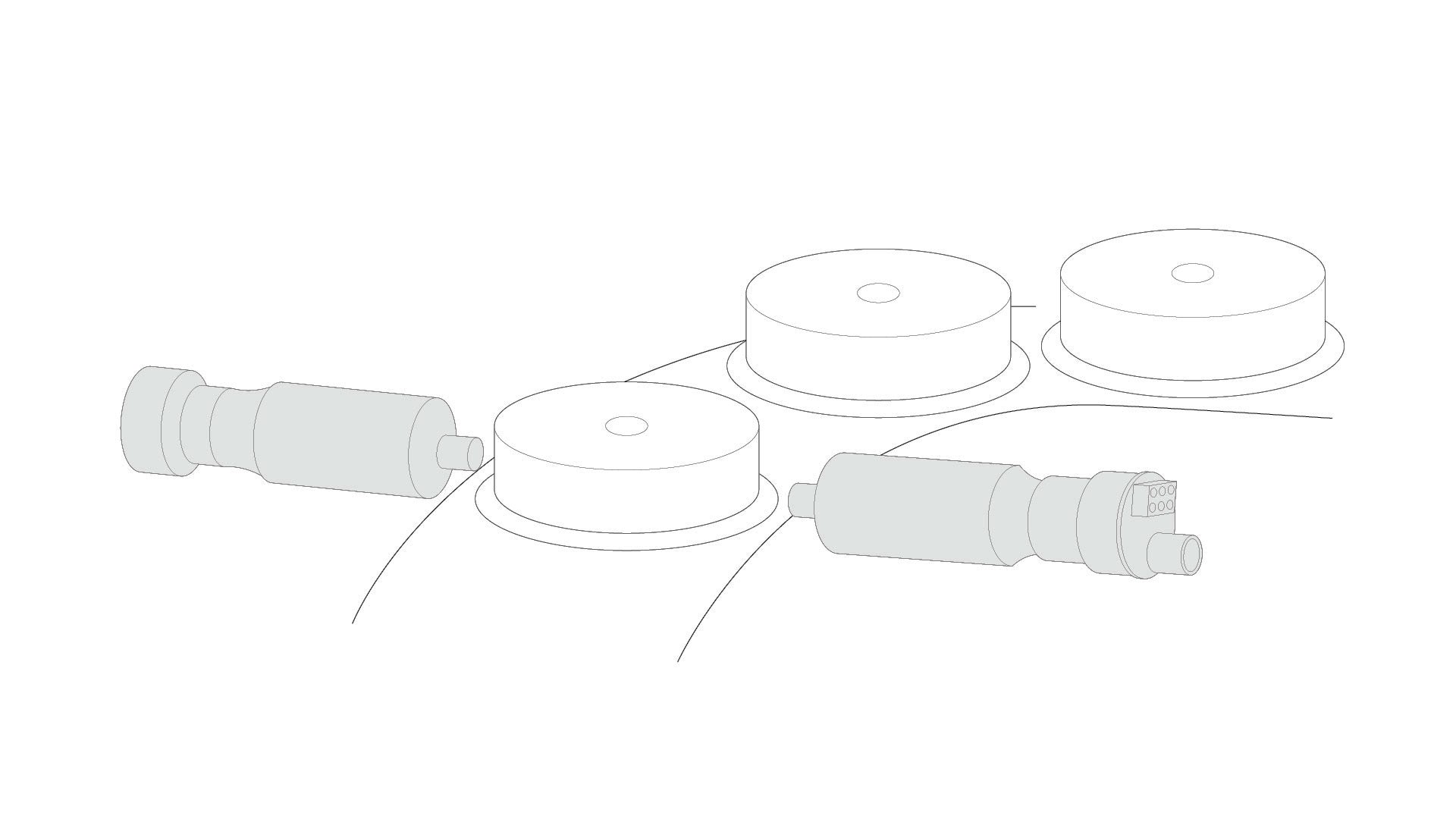

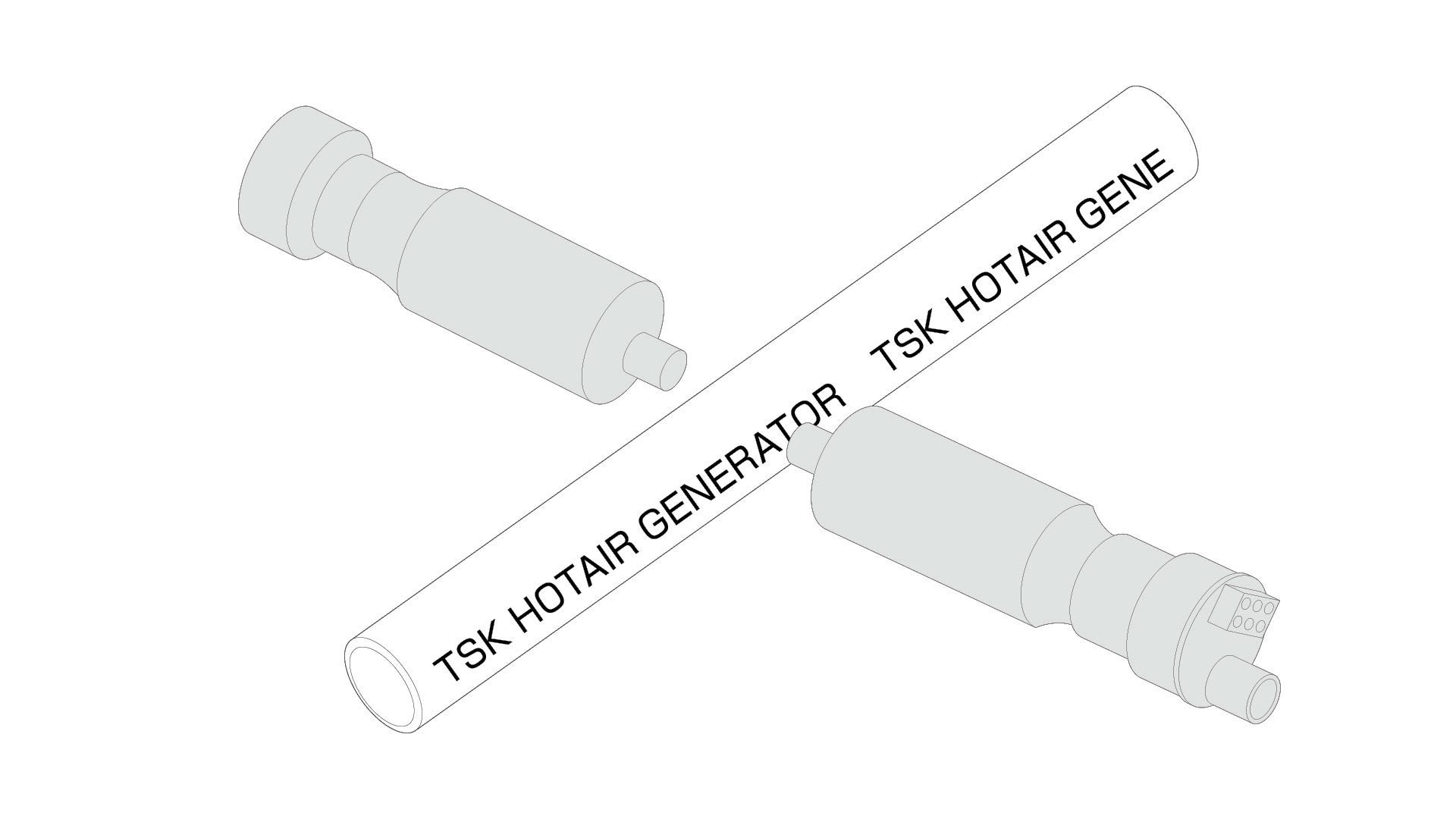

Spot Heater Overview

- Maximum continuous operating temperature:800 °C

- Heater capacity: 0.55 kW to 3 kW

- Equipped with

- Sensor A: detects hot-air outlet temperature

- Sensor B: detects hot-start temperature & prevents overheating

- When used with the Multi-Controller TRC202,

- Heater element life is extended

- Enables stable long-duration operation at 800 °C

- Improves hot-start operation, heater protection, and temperature-control performance

→ Ensures precise and reliable temperature management

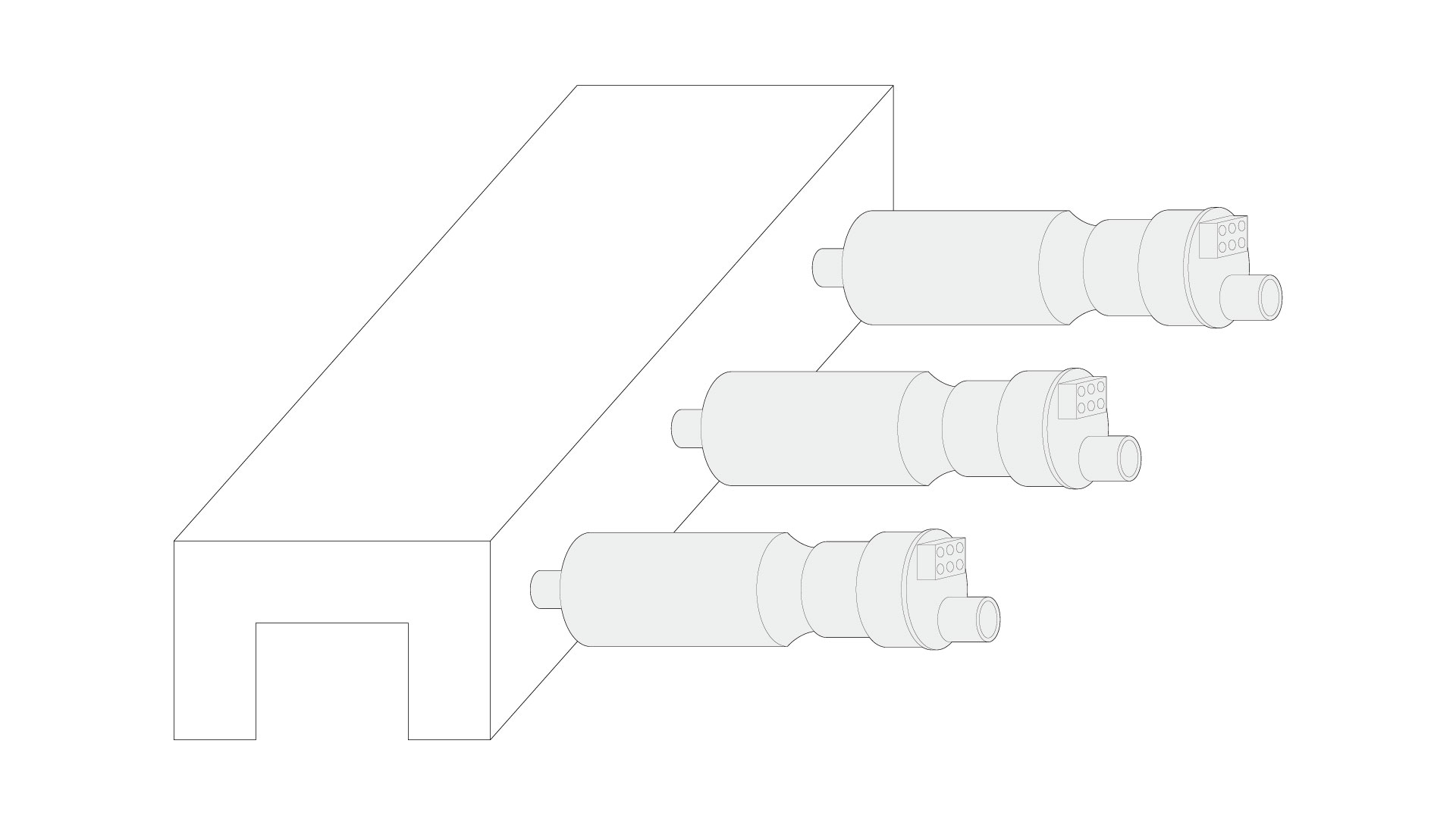

Note: One Multi-Controller TRC202 is required per Spot Heater unit.

When the Multi-Controller is not used (e.g., when using a customer-made control circuit),

the maximum hot-air temperature is limited to 500 °C.

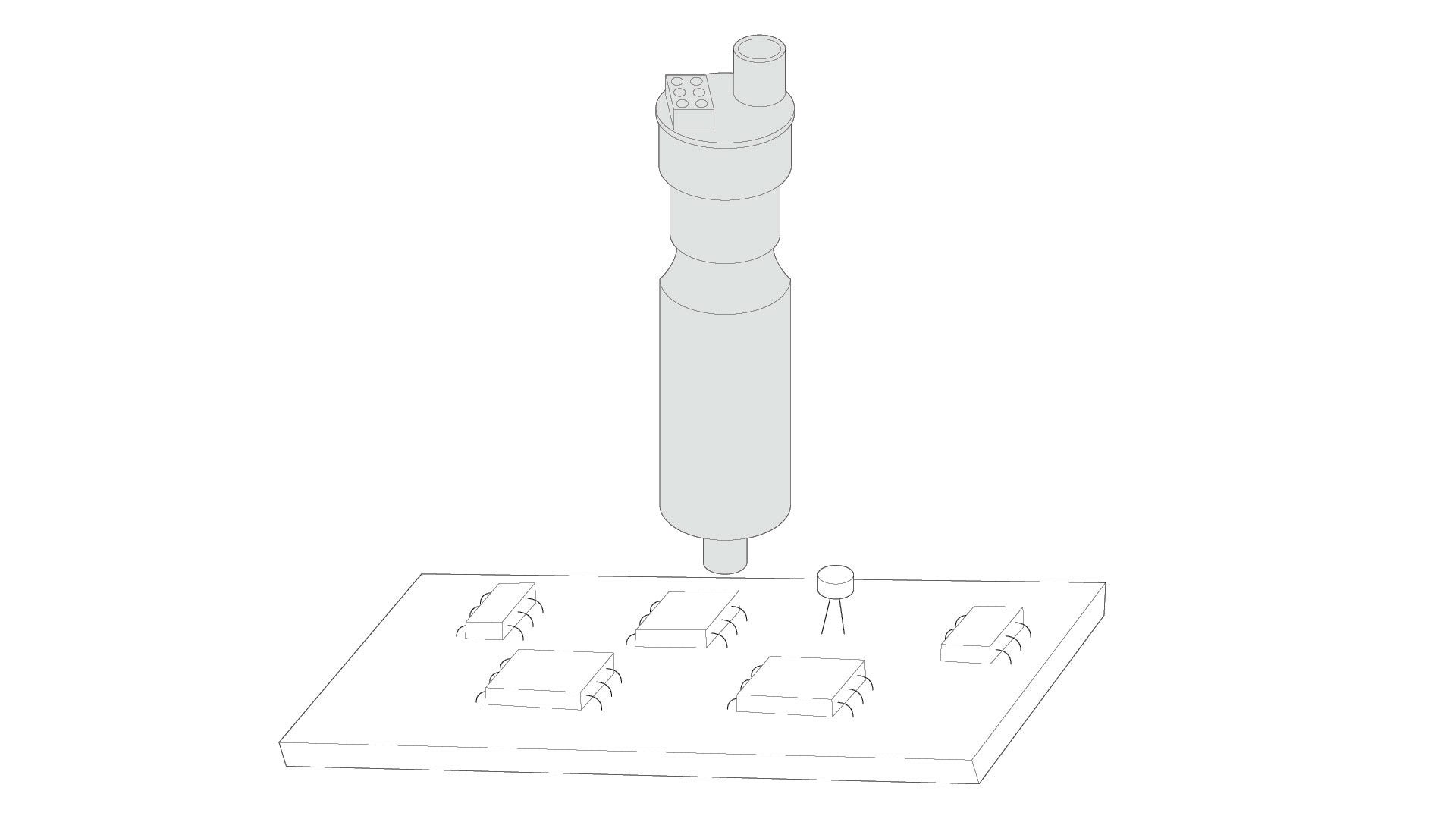

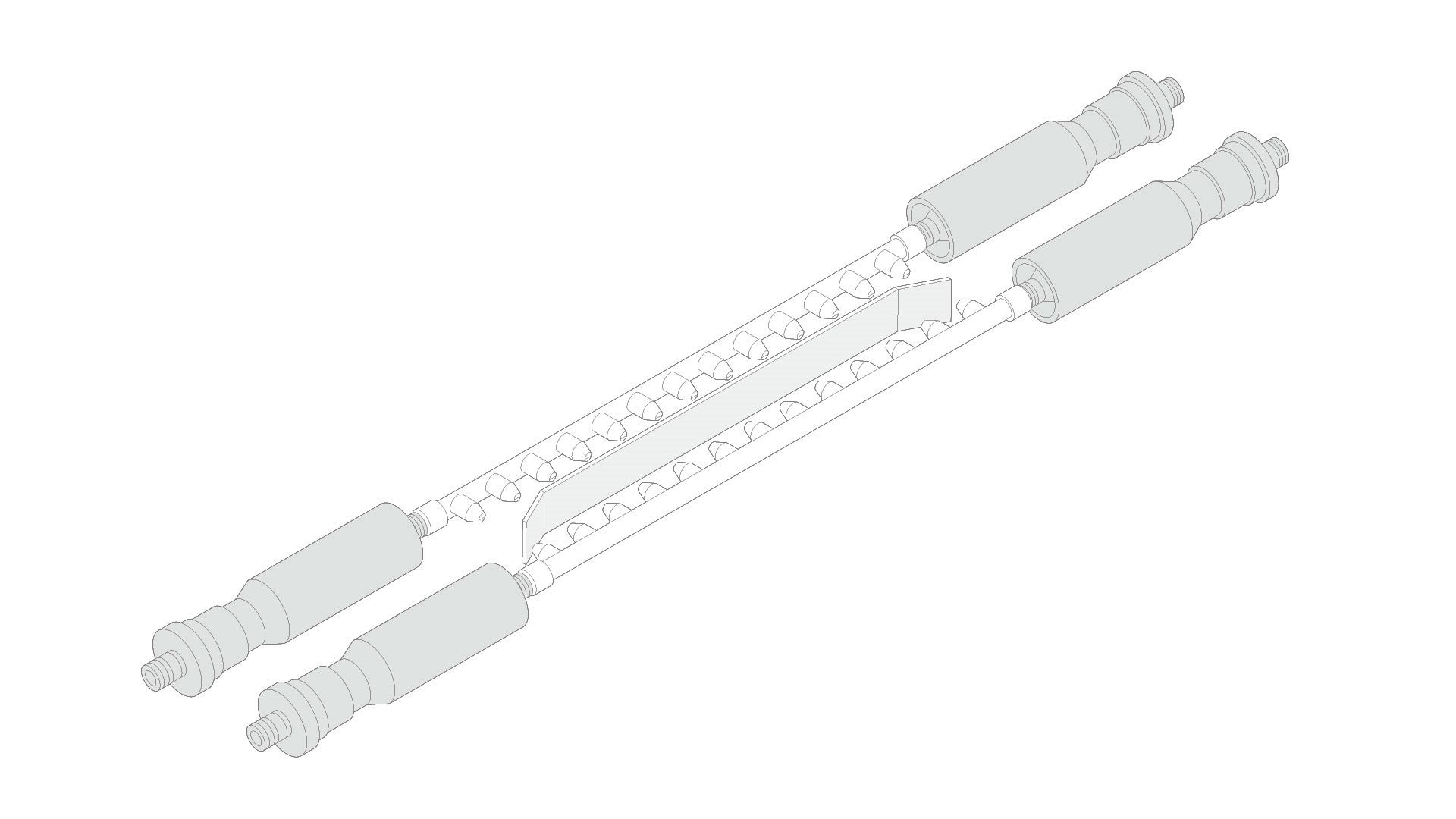

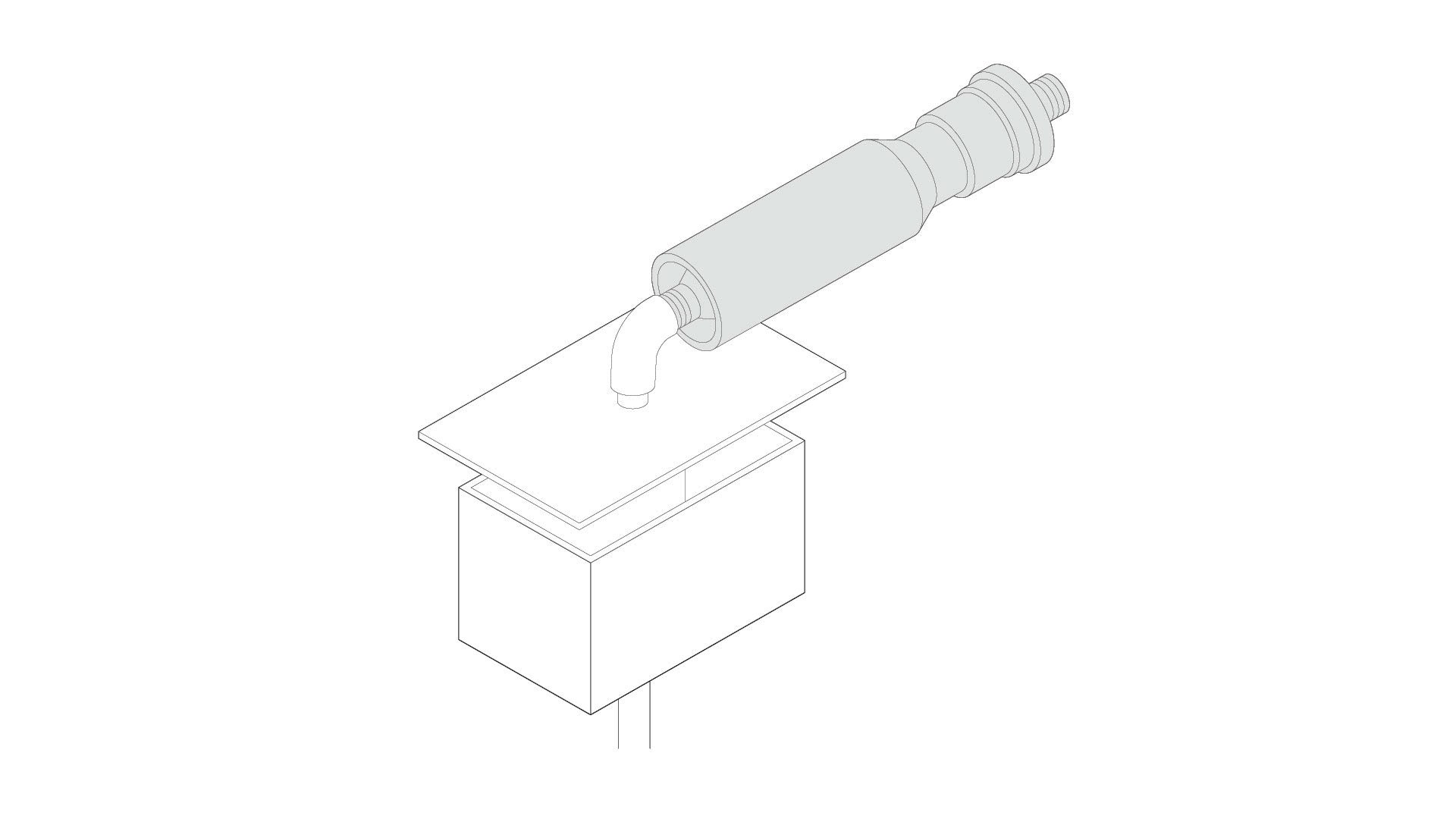

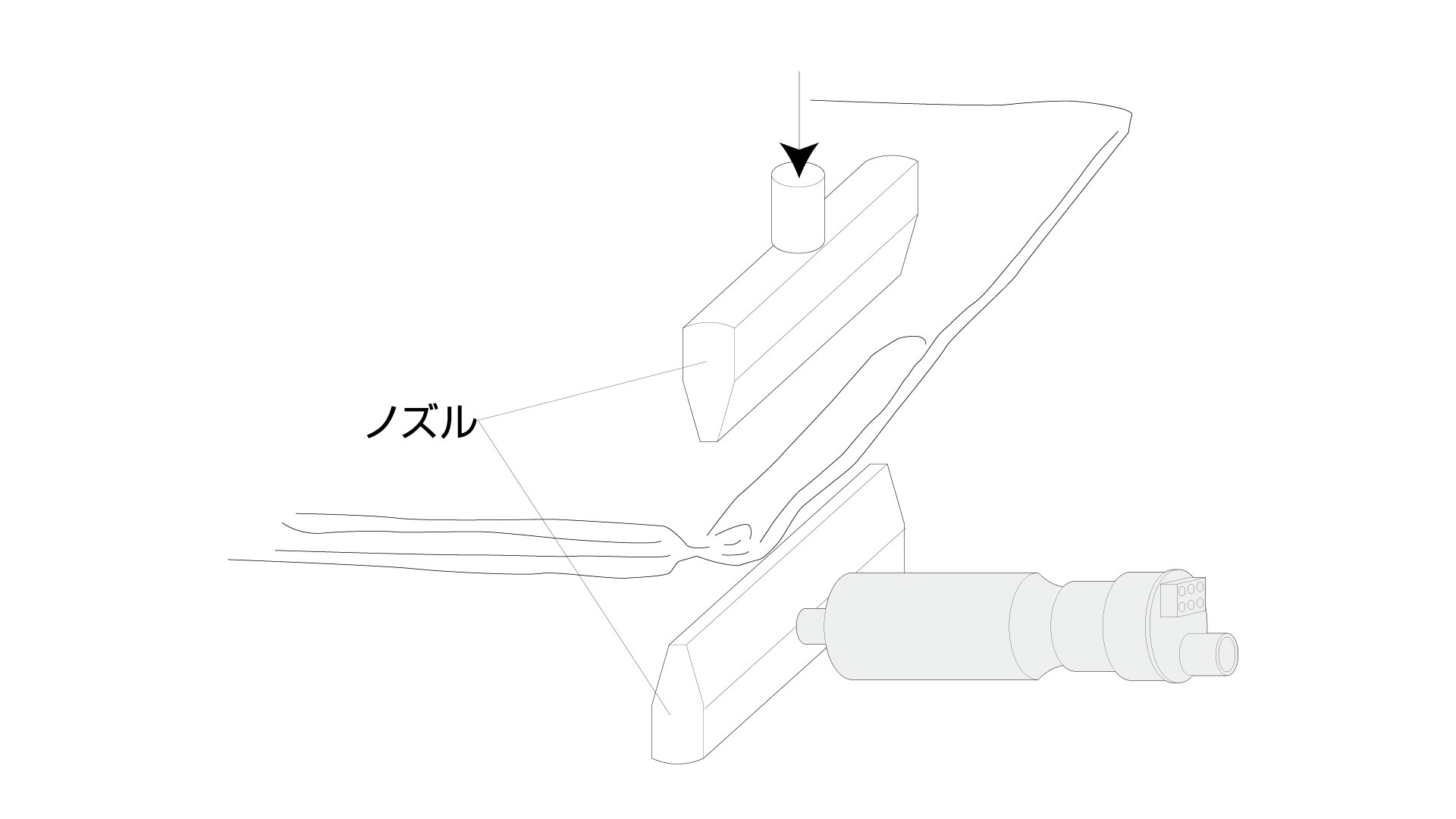

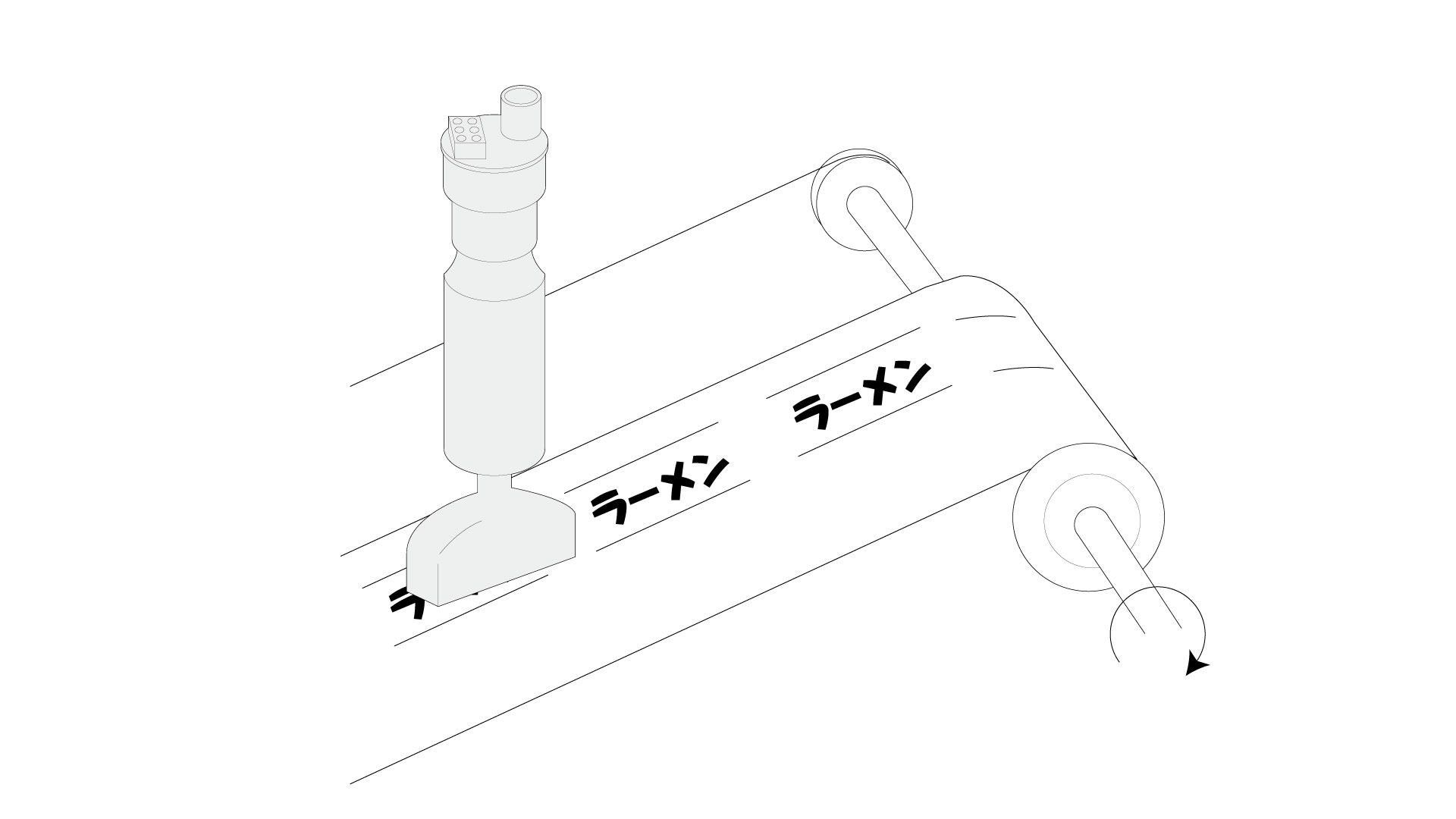

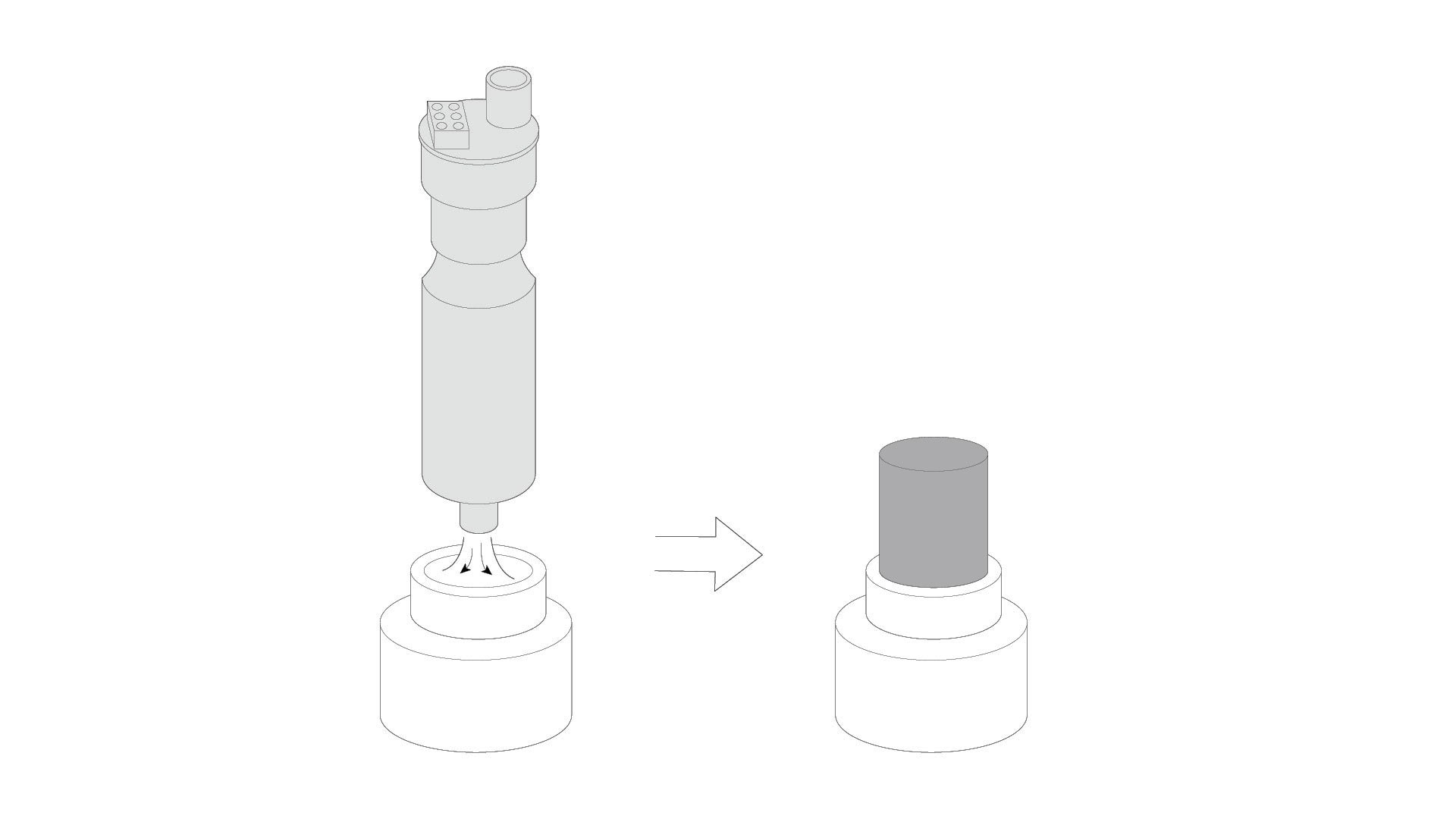

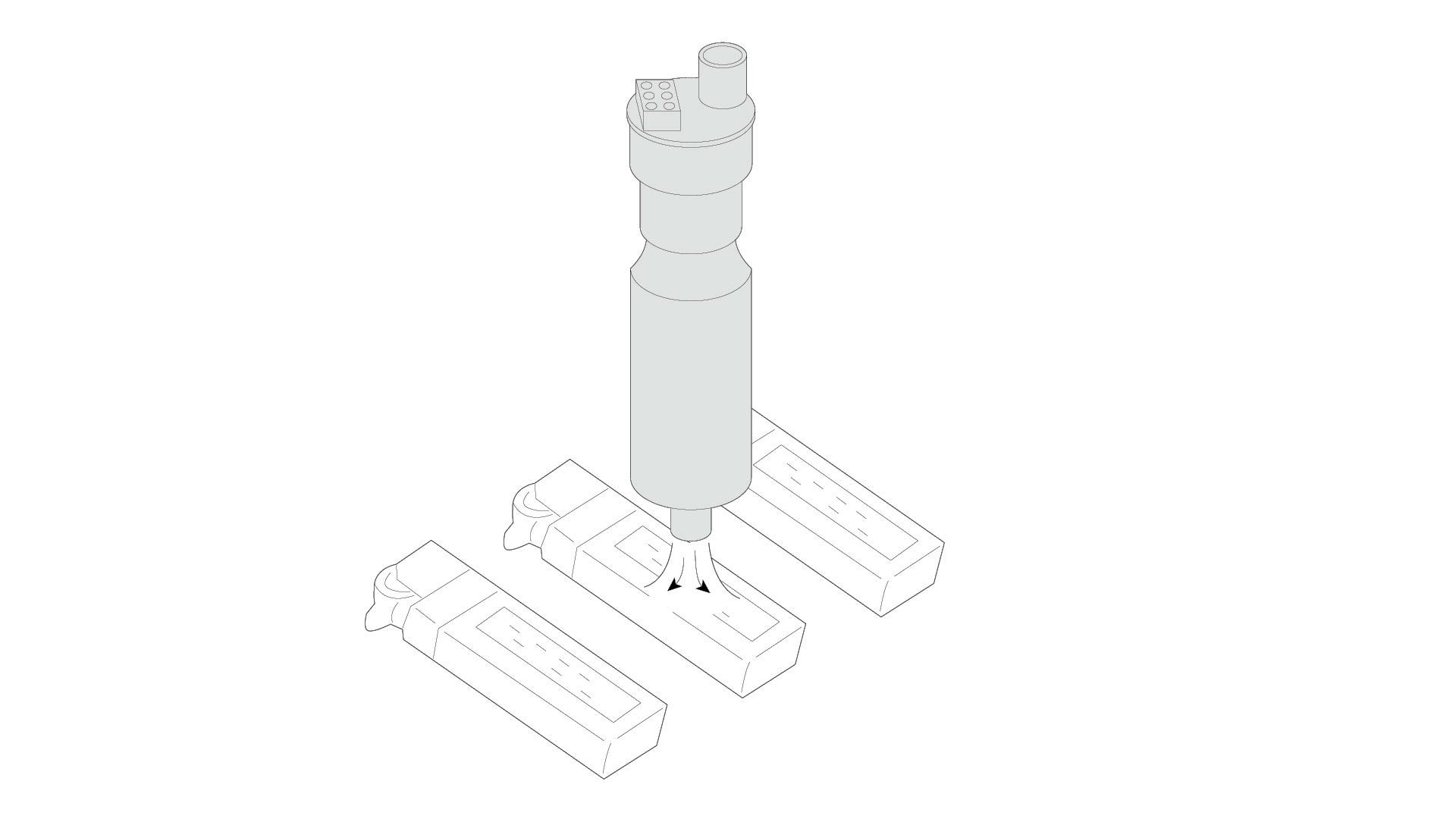

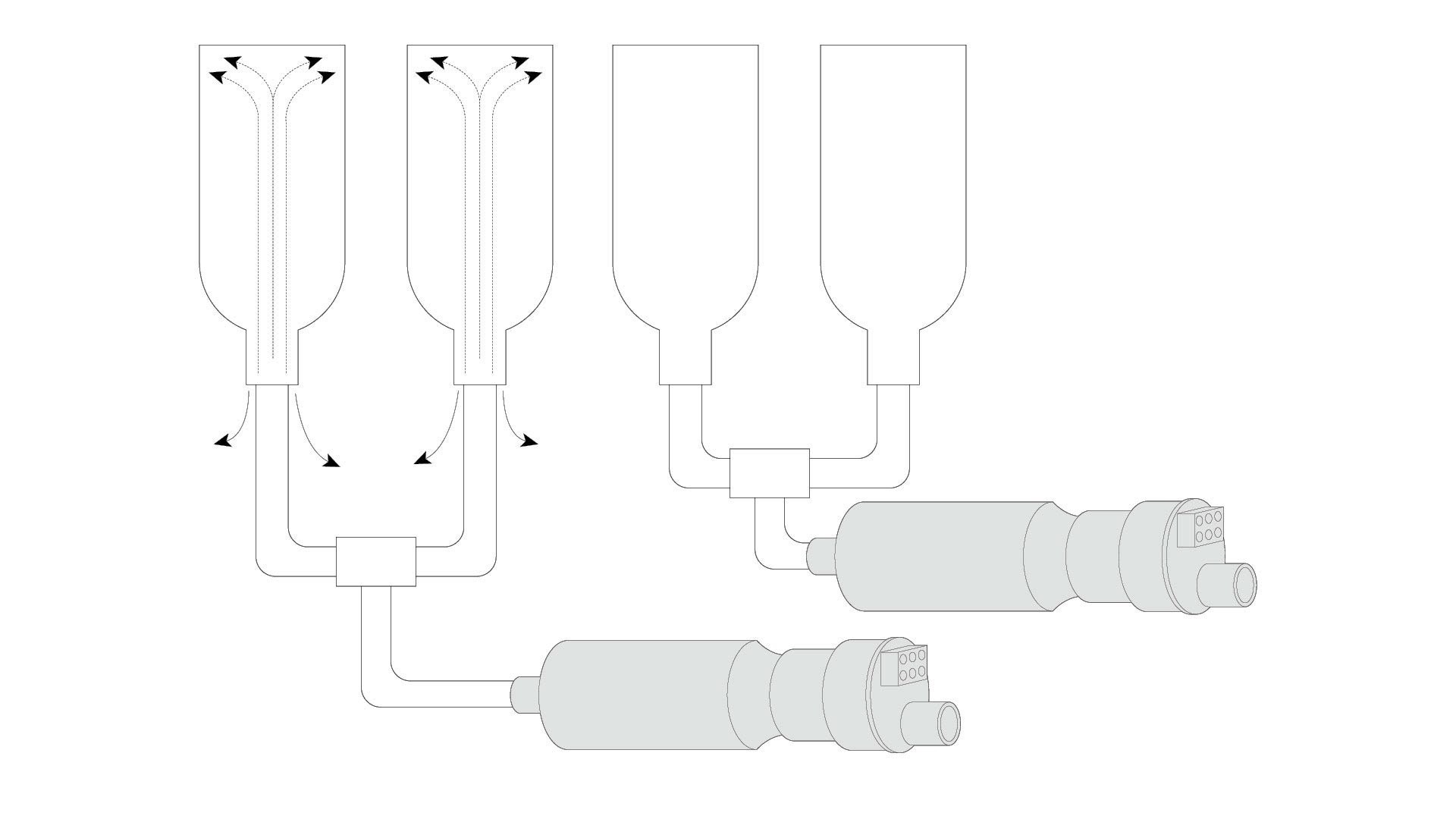

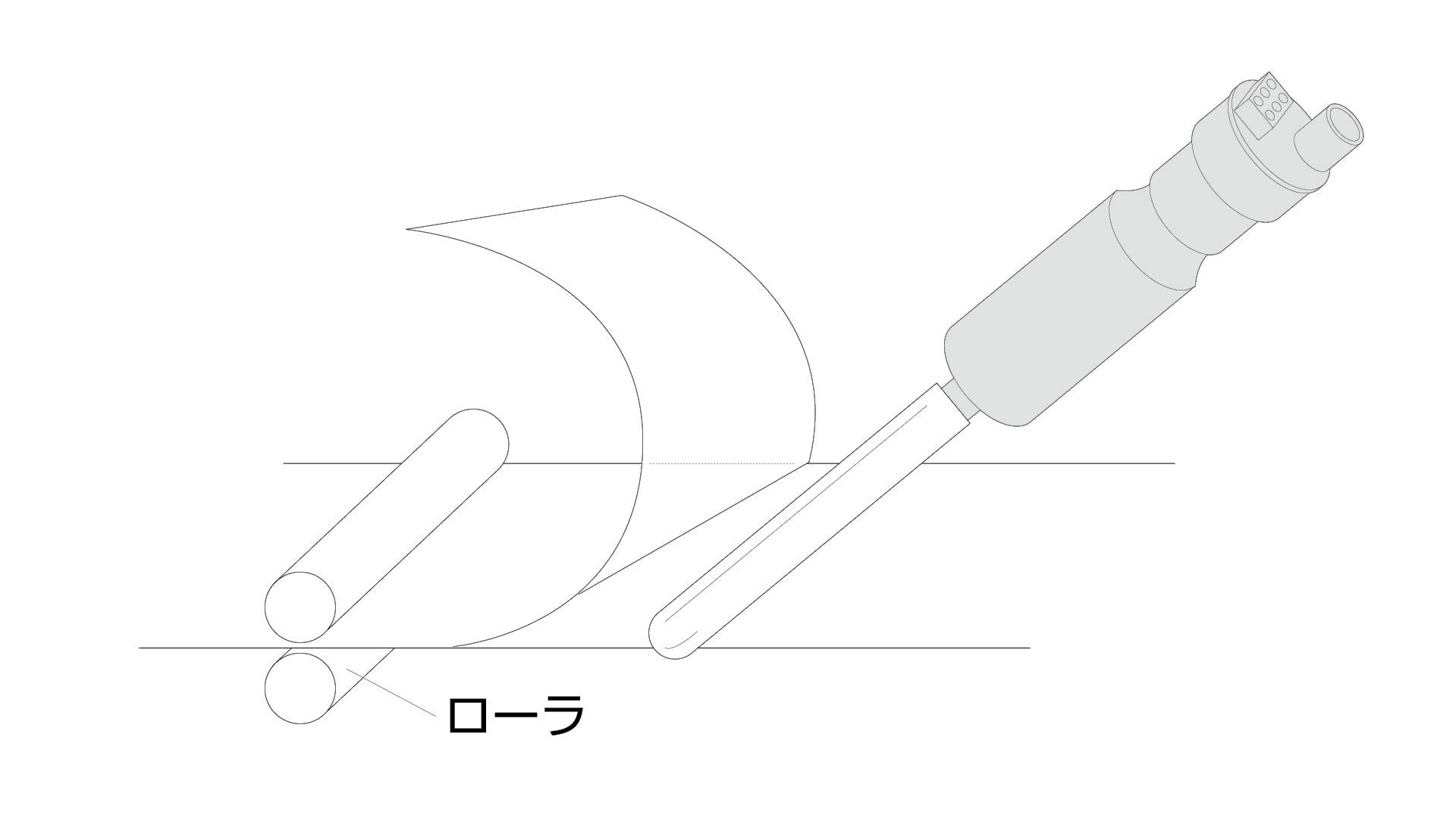

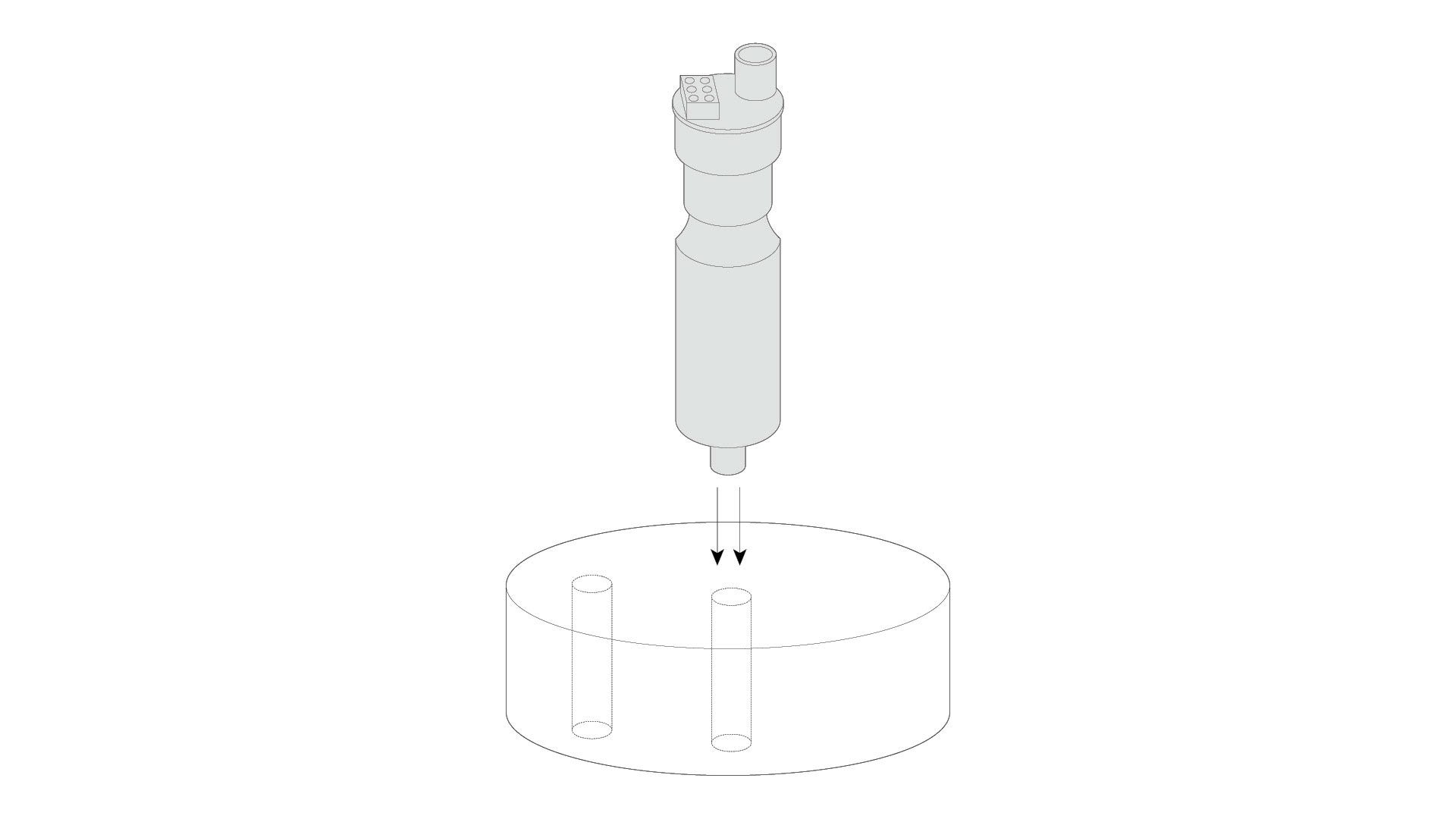

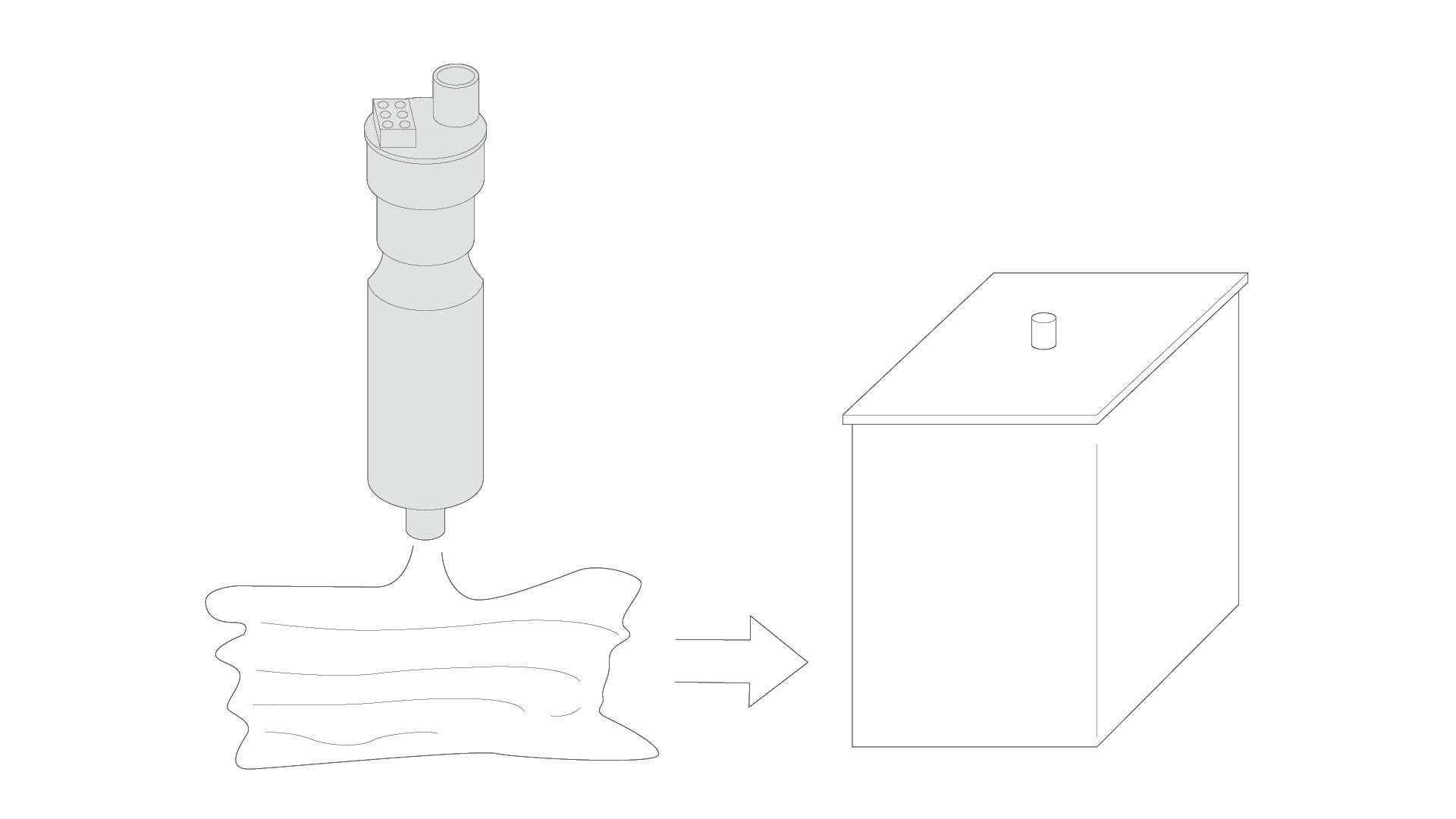

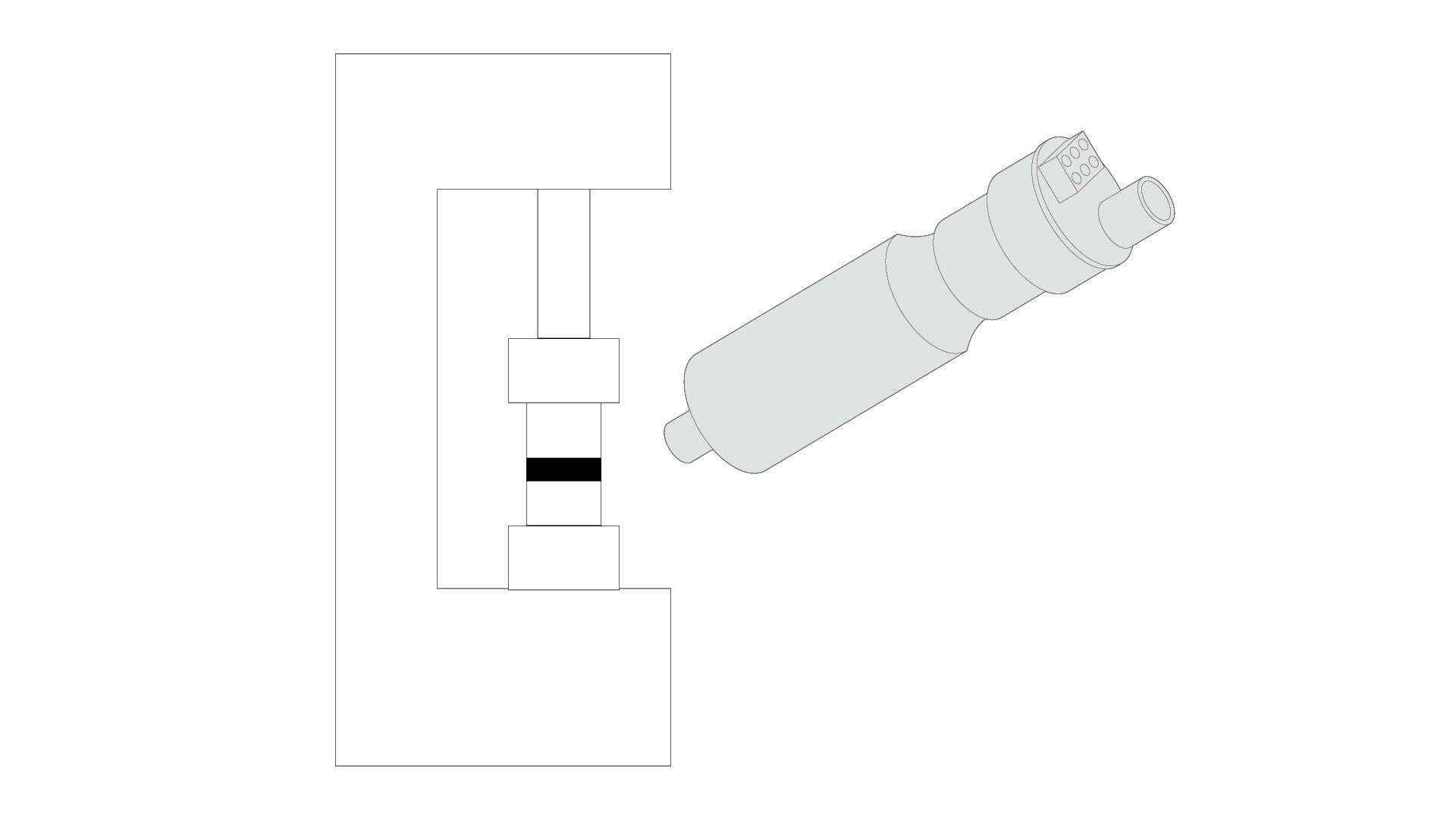

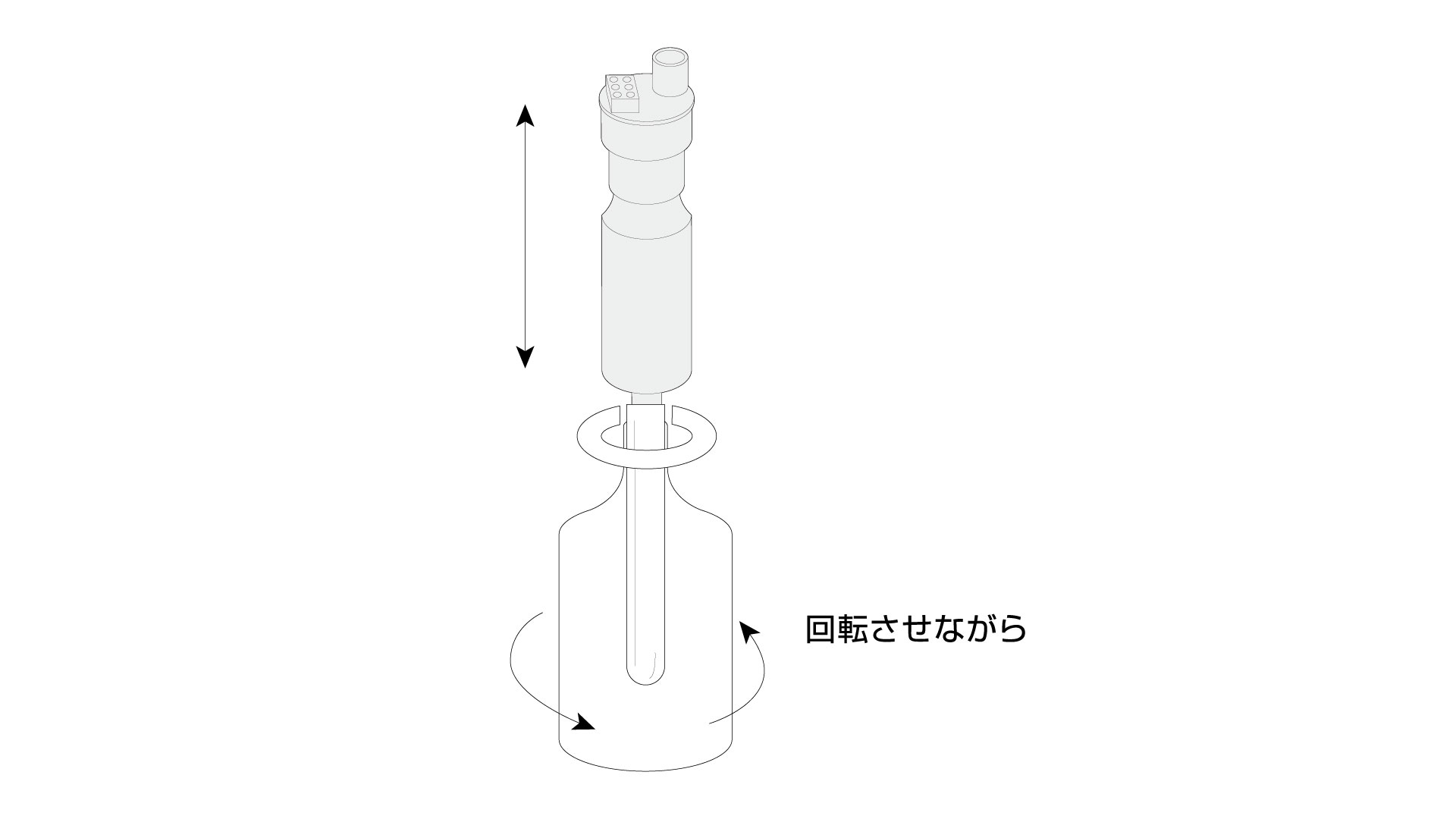

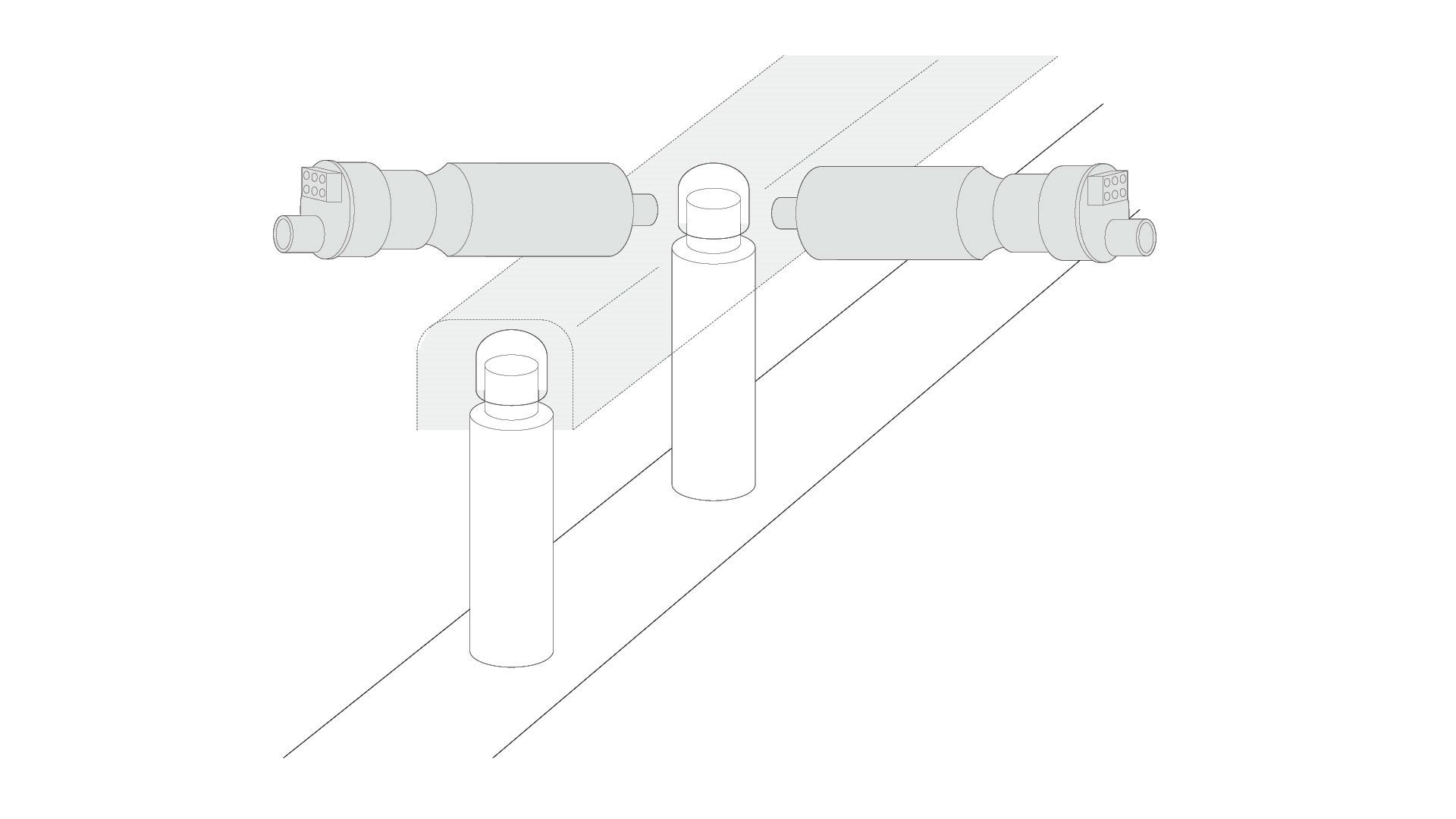

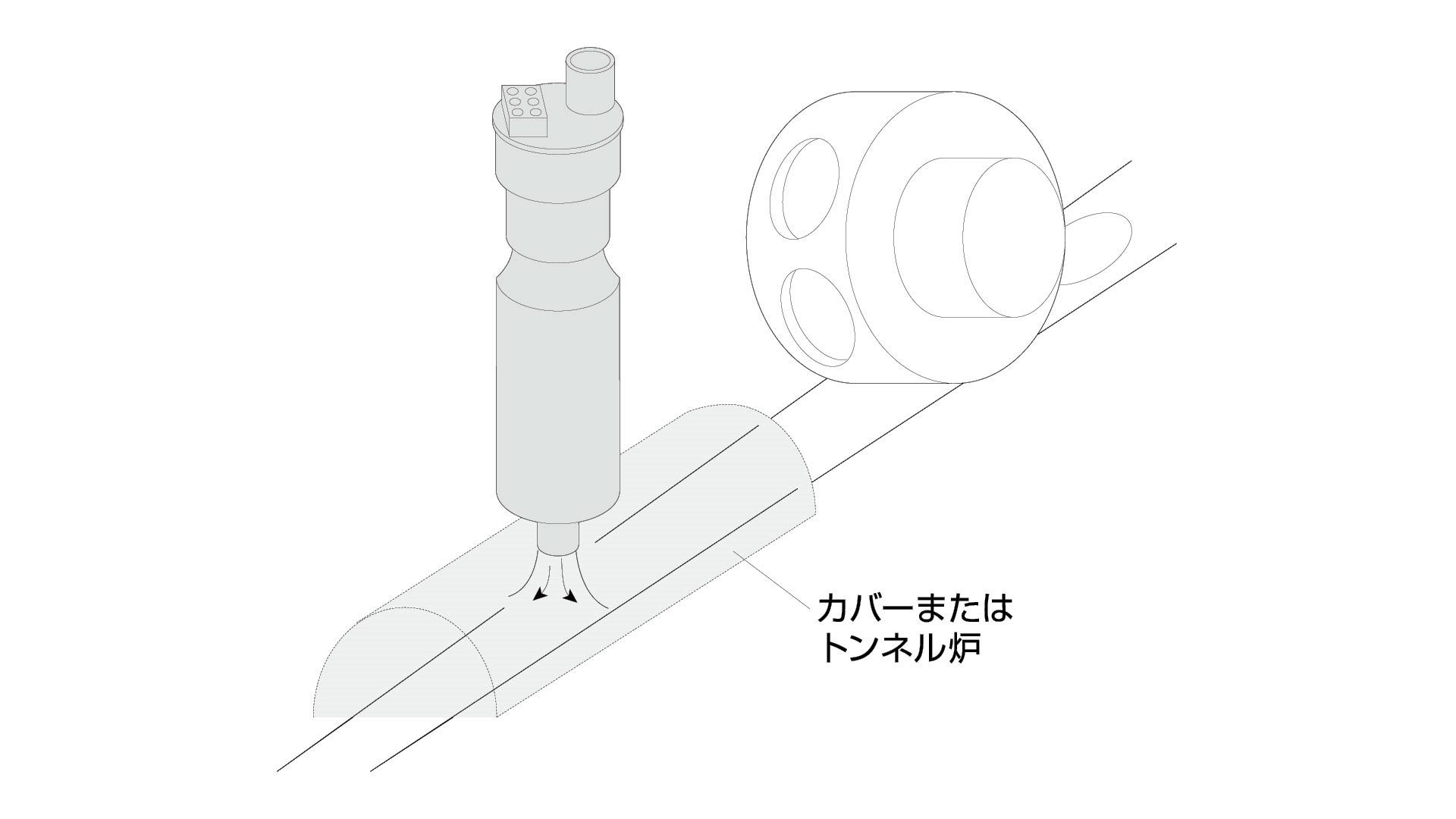

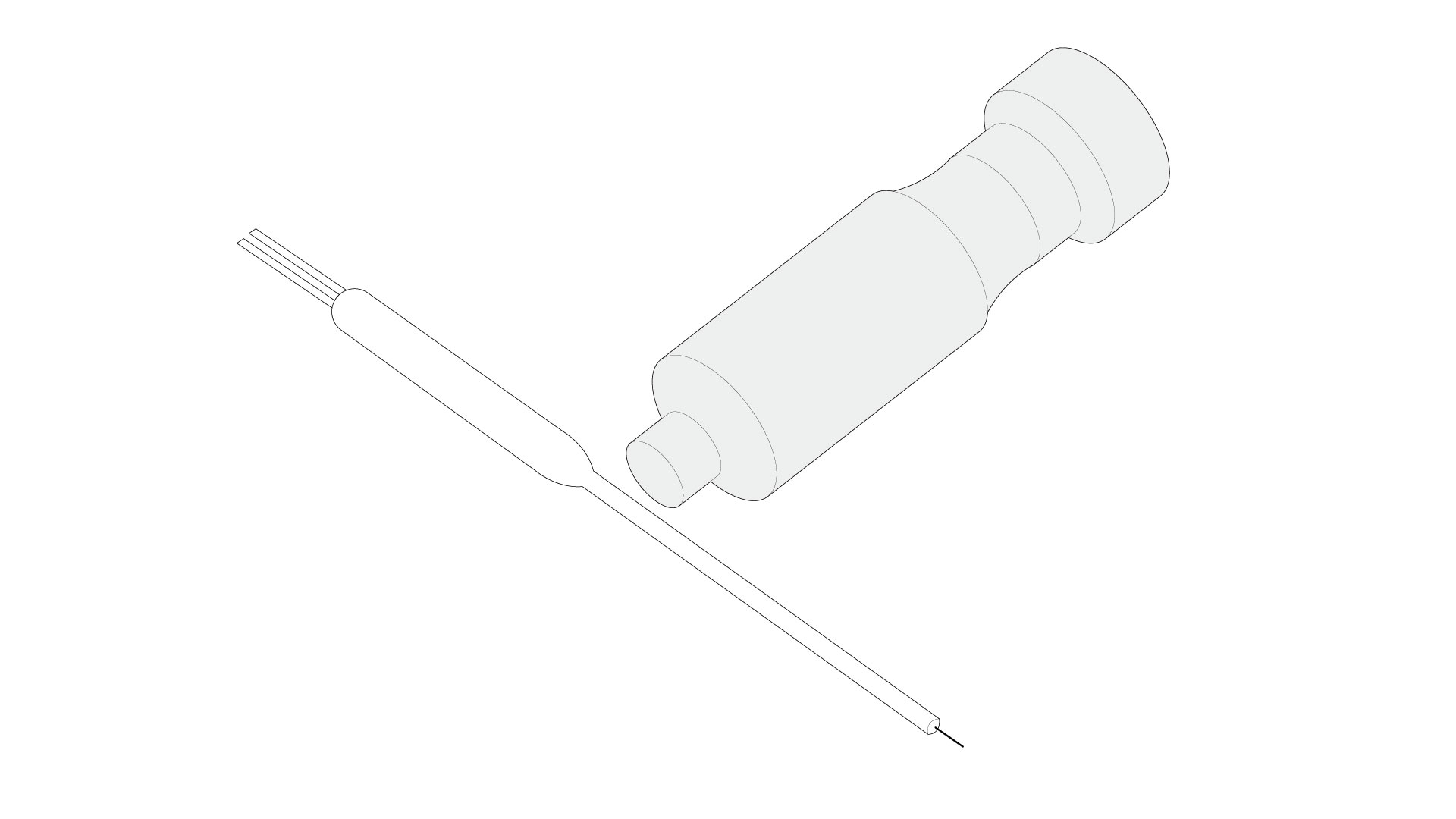

Typical Applications

Note: Some illustrations may contain Japanese text.

Our products can also be used for many other applications. Please feel free to contact us for further consultation.

Standard Specifications List

| Model |

SH02 |

|

|---|---|---|

| Model Nos. | 1100-0.7K | 1200-055K |

| Power Supply | Single-phase 100 V, 50/60 Hz | Single-phase 200 V, 50/60 Hz |

| Heater Capacity | 0.7 kW | 0.55 kW |

| Max Outlet Air Temp. | 800 °C | |

| Max Inlet Air Temp. | 70 °C | |

| Max Airflow | 120 L/min | |

| Min Airflow | 5 L/min | |

| Heater Case Pressure Rating |

Approx 490 kPa (at room temperature) |

|

|

|

|

| Model |

SH22 |

||||

|---|---|---|---|---|---|

| Model Nos. | 1200-06K | 1200-08K | 1200-1.2K | ||

| Power Supply | Single-phase 200 V, 50/60 Hz | ||||

| Heater Capacity | 0.6 kW | 0.8 kW | 1.2 kW | ||

| Max Outlet Air Temp. | 800 °C | ||||

| Max Inlet Air Temp. | 70 °C | ||||

| Max Airflow | 400 L/min | ||||

| Min Airflow | 15 L/min | ||||

| Heater Case Pressure Rating |

Approx 490 kPa (at room temperature) |

||||

|

|

||||

| Model |

SH31 |

|

|---|---|---|

| Model Nos. | 1200-2K | 1200-3K |

| Power Supply | Single-phase 200 V, 50/60 Hz | |

| Heater Capacity | 2 kW | 3 kW |

| Max Outlet Air Temp. | 800 °C | |

| Max Inlet Air Temp. | 70 °C | |

| Max Airflow | 1050 L/min | |

| Min Airflow | 60 L/min | |

| Heater Case Pressure Rating |

Approx 490 kPa (at room temperature) |

|

|

|

|

| Model |

TRC202 |

|

|---|---|---|

| Heater Control Capacity | Up to 2 kW (100 V) | Up to 4 kW (200 V) |

| Power Supply | Compatible with Single-phase 100 V / 200 V, 50/60 Hz | |

|

|

|