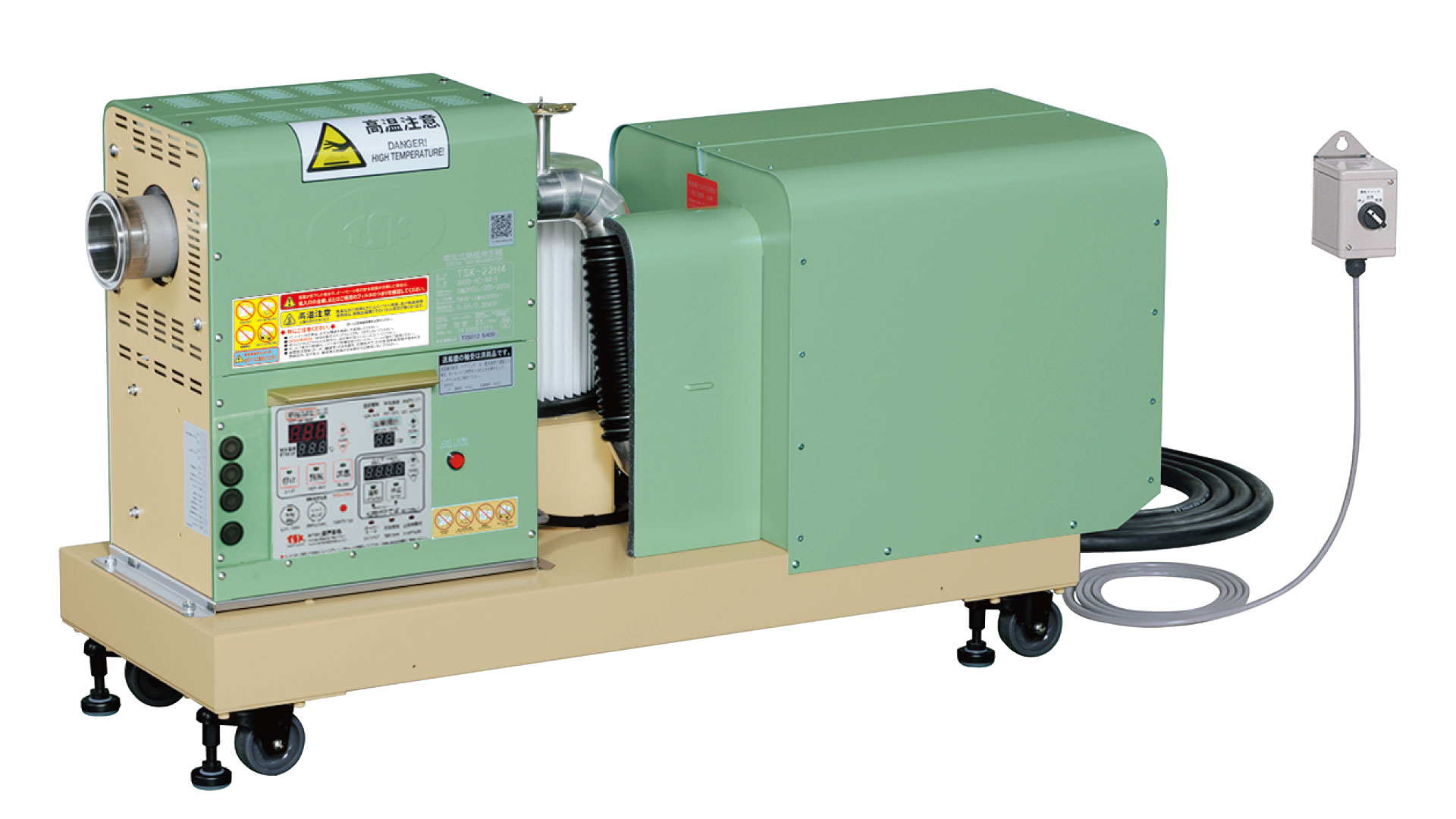

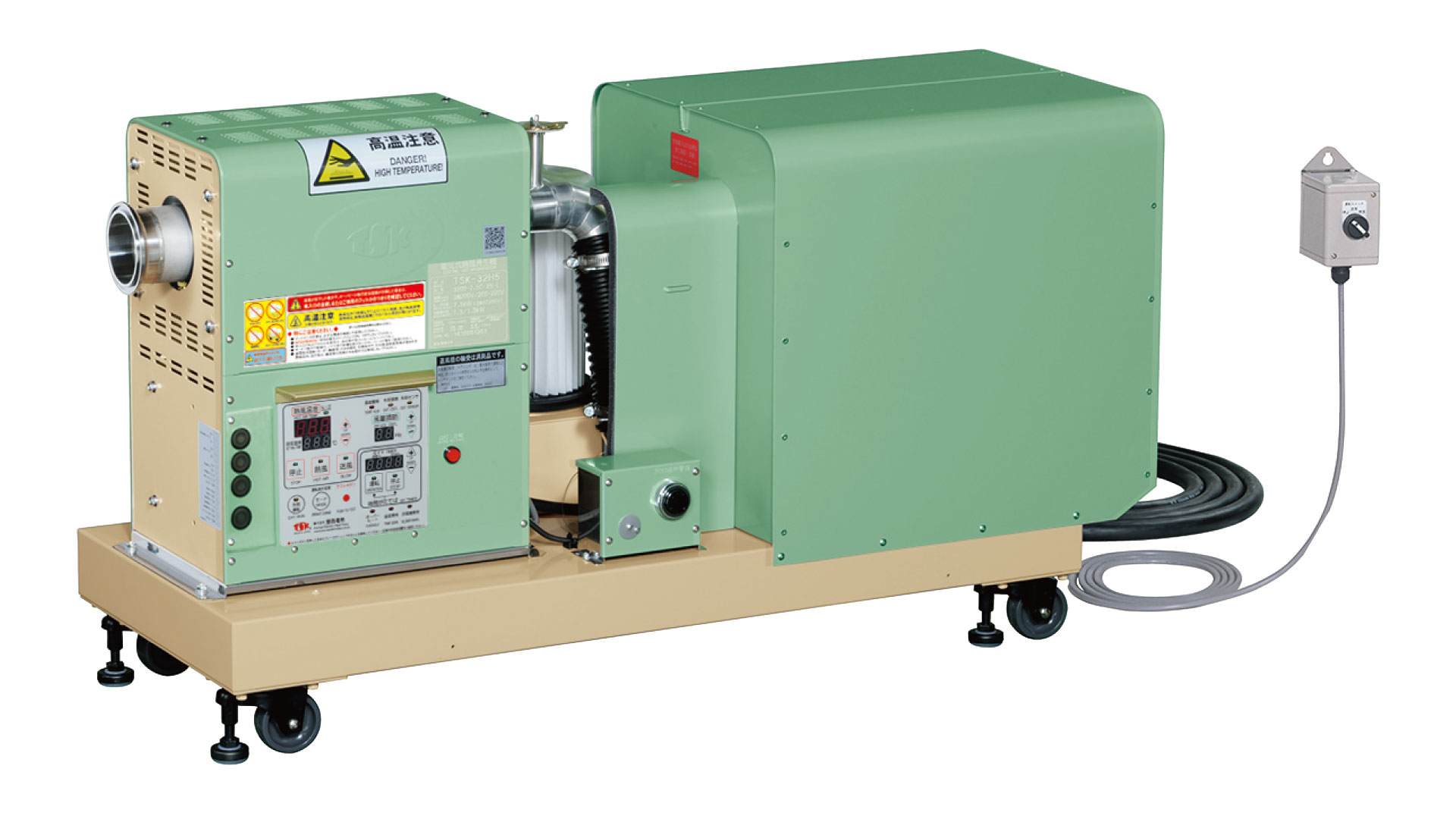

H Series (High Static Pressure Type)

The Definitive Electric Hot Air Generator!

- The H Series is a compact and lightweight electric hot air generator equipped with a high static pressure regenerative blower (vortex type), providing outlet static pressure ranging from 10.1 to 24.1 kPa.

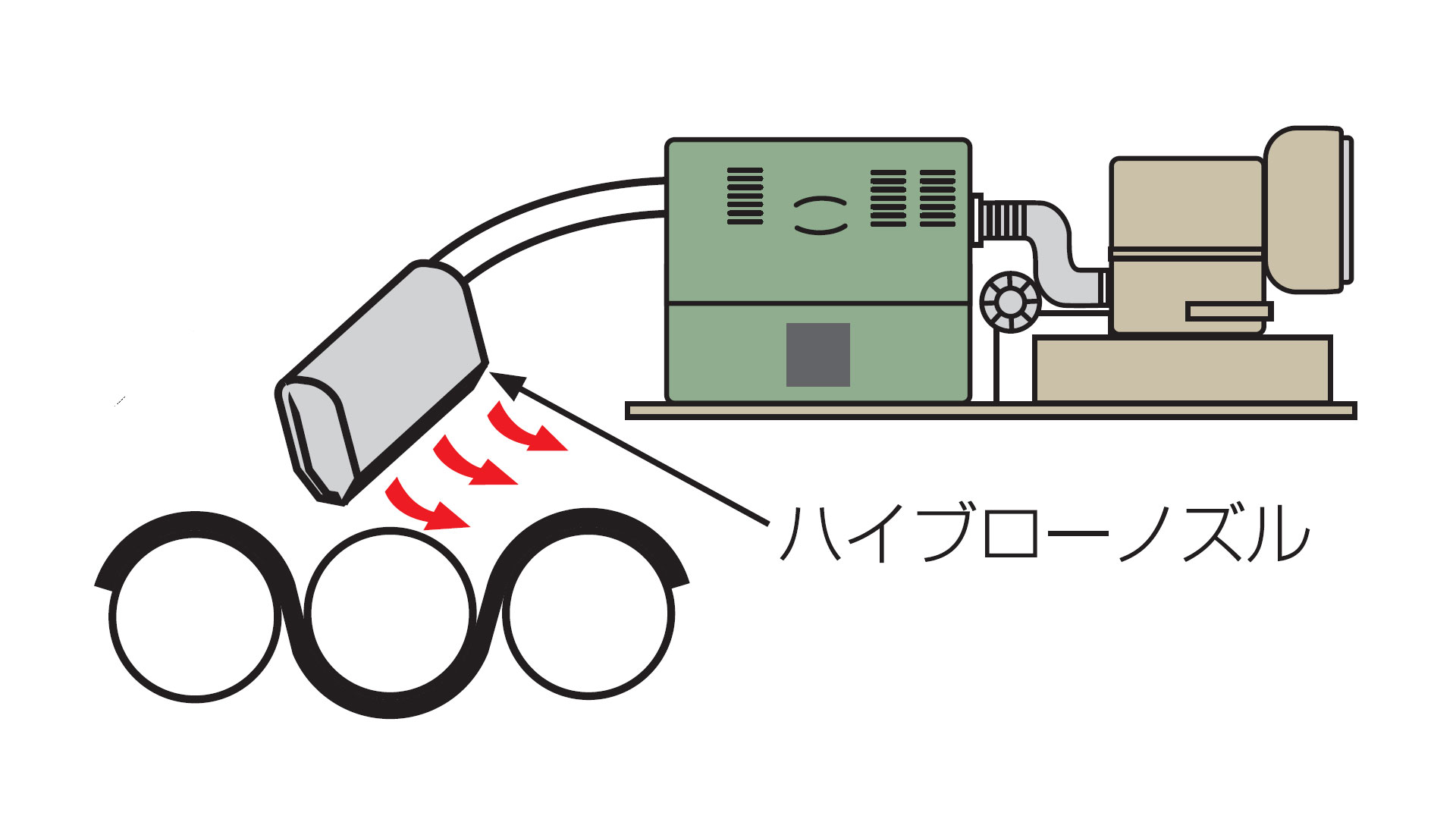

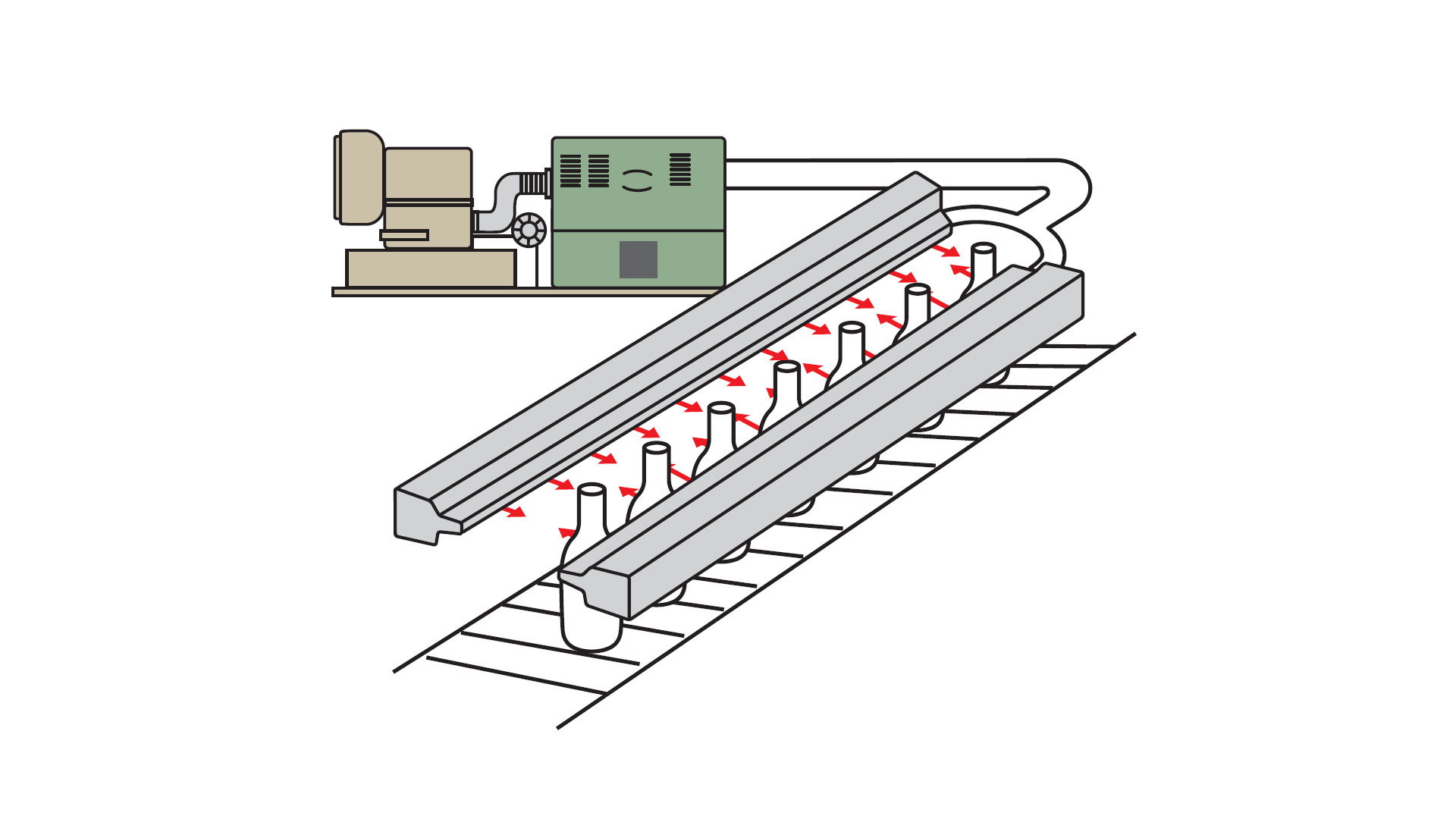

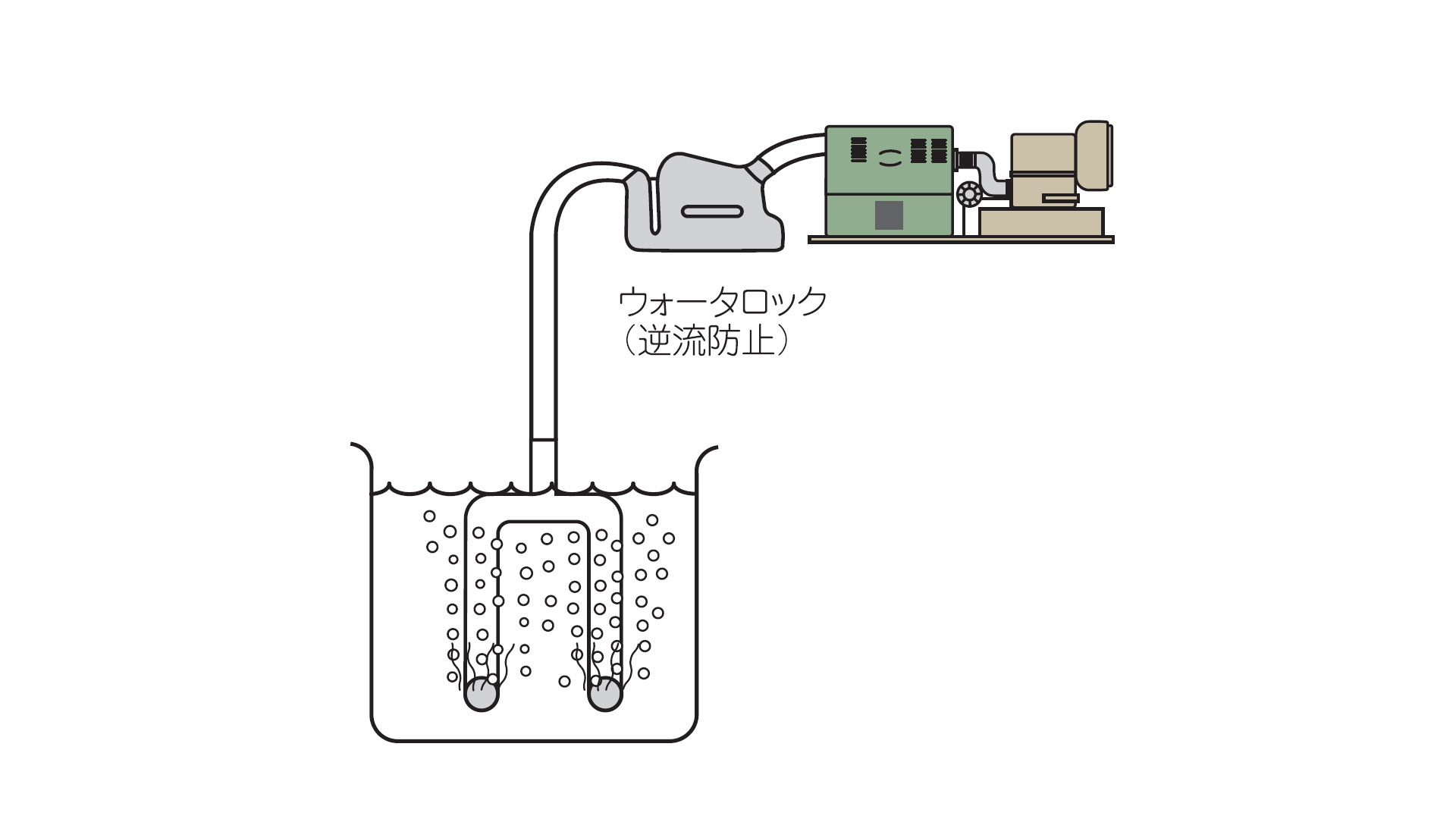

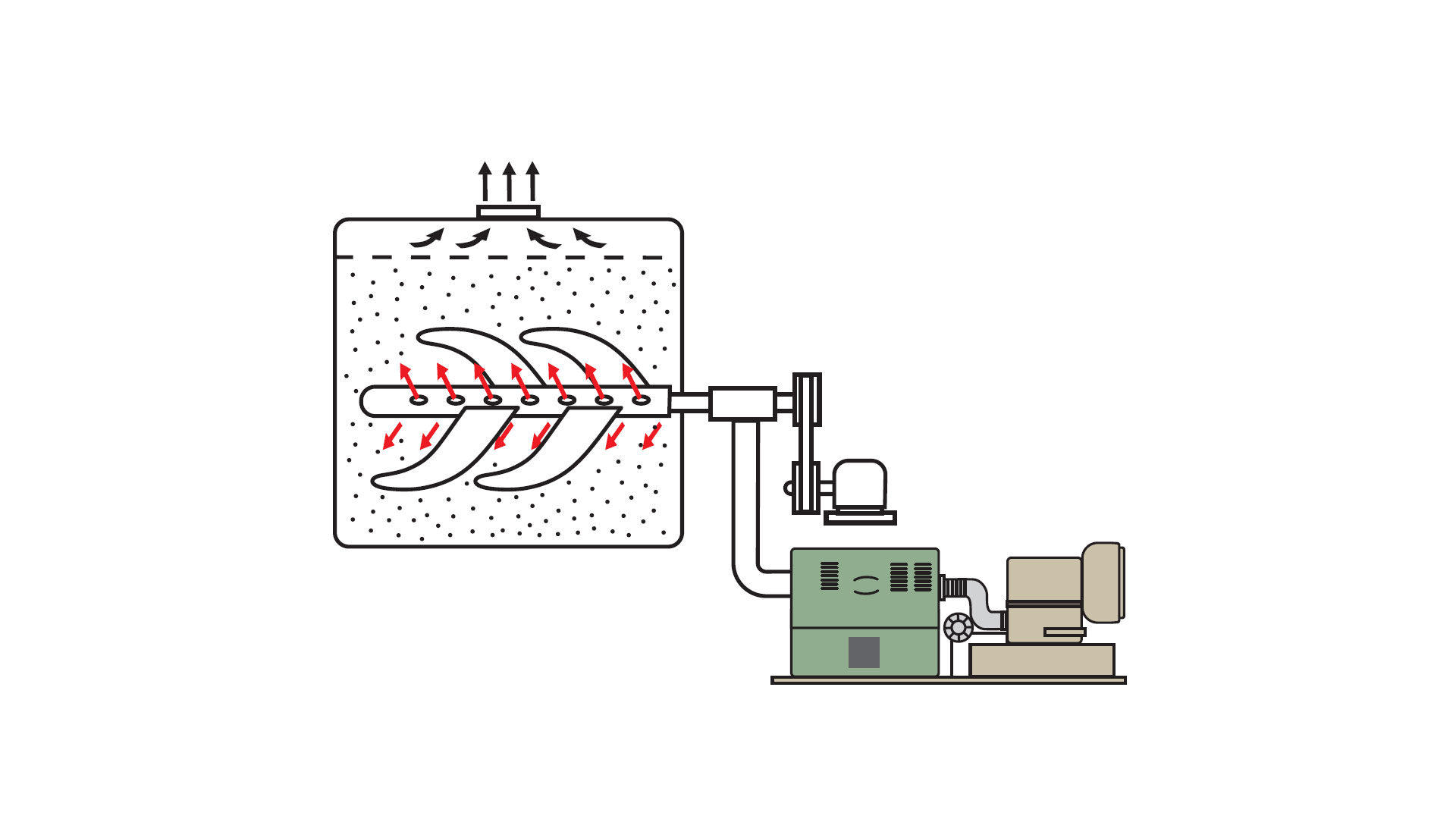

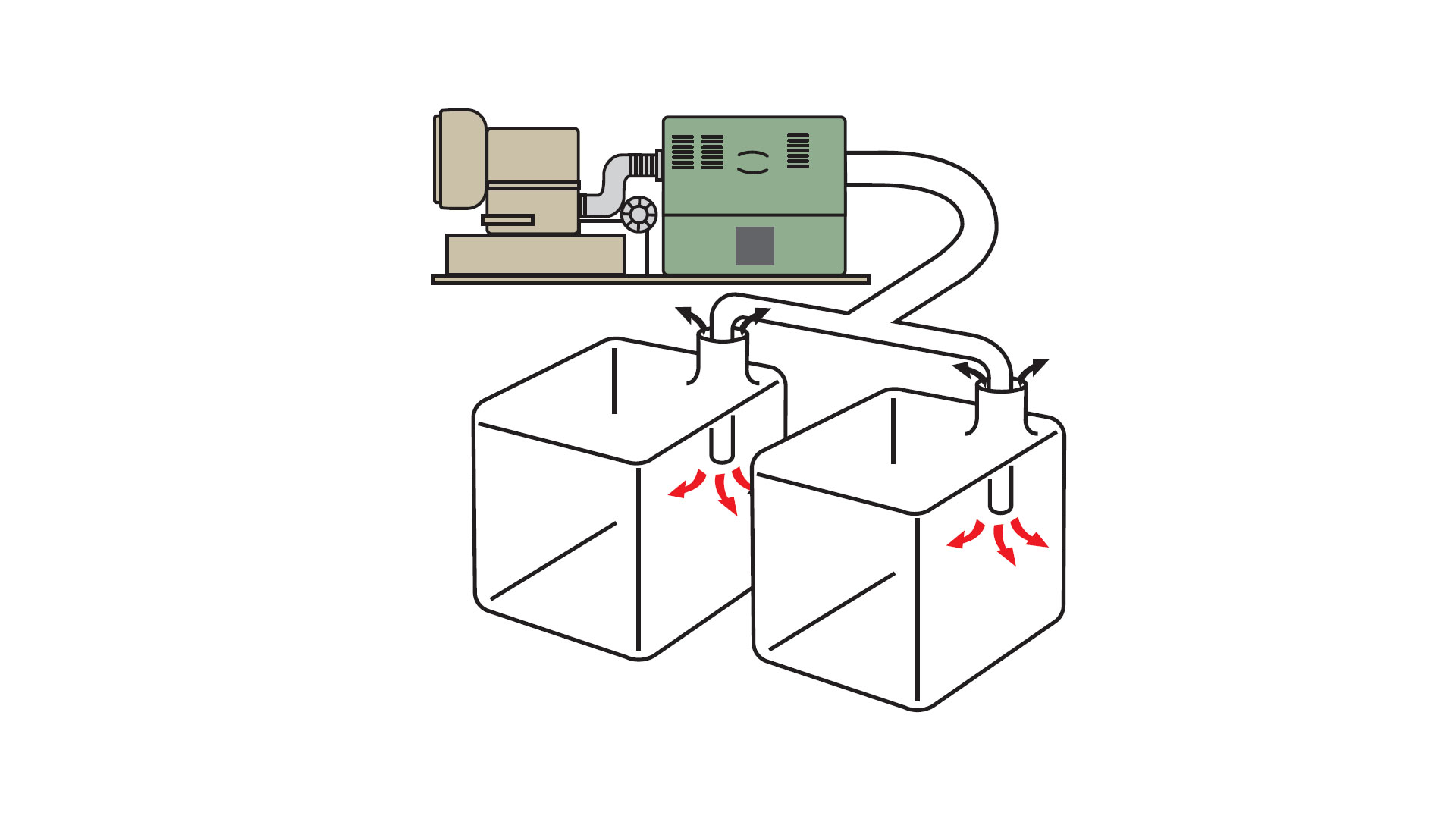

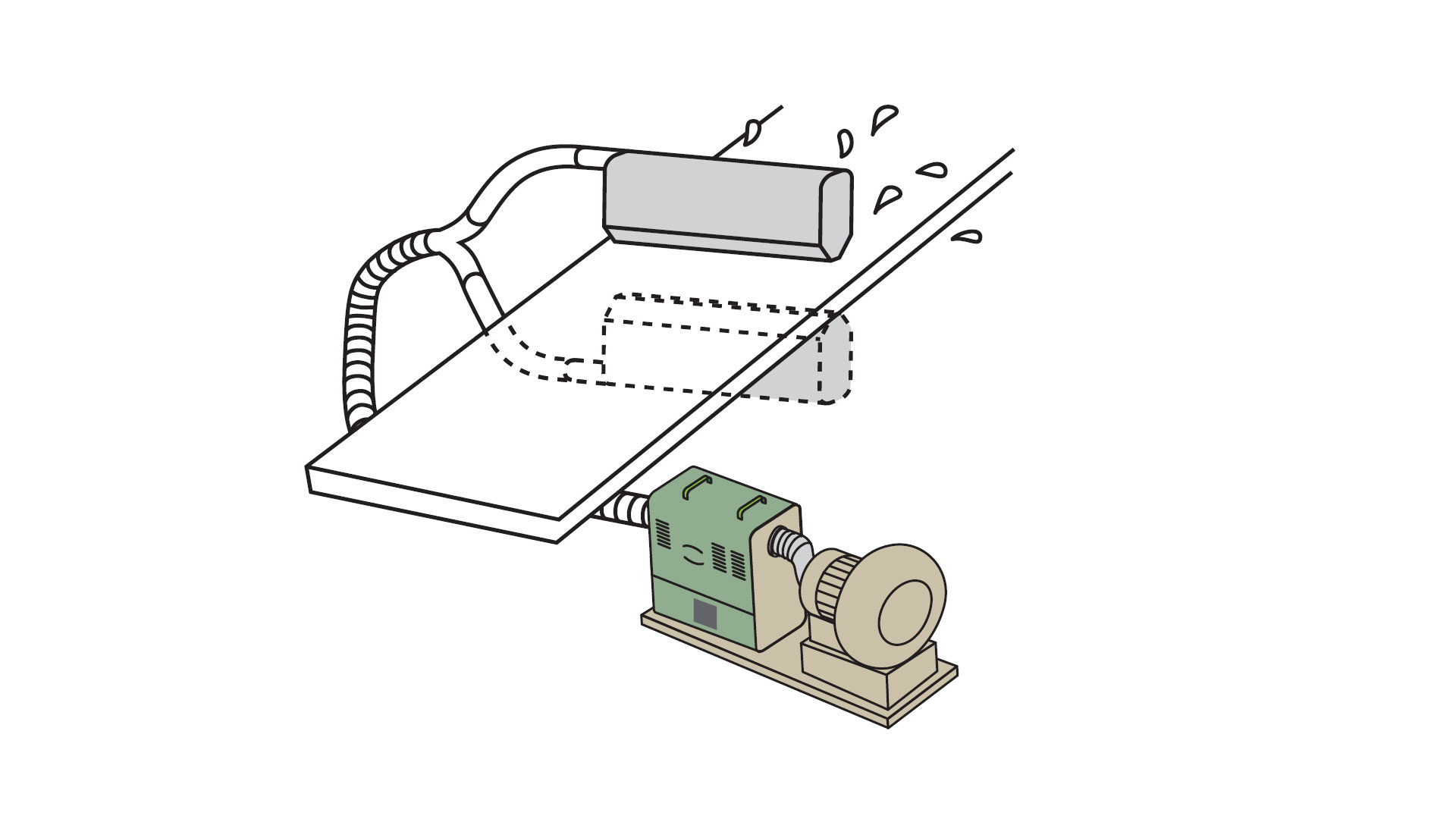

- By using various nozzles in combination, the unit can deliver

high-temperature, high-velocity hot air, making it suitable for applications such as rapid heating and rapid water removal drying. It is particularly well suited for processes requiring high static pressure at the outlet side. - Operation is simple—just connect the power supply cable to begin use.

- An intermittent operation function is provided as standard.

H Series Overview

- Maximum continuous operating temperature: 350 °C

- Heater capacity: 3 kW to 12 kW

- Equipped with a high-efficiency honeycomb block heater

- Optional inverter for airflow control (variable 20–60 Hz) → Energy-saving

- High-performance air filter installed as standard on all models → Energy-saving

- High static pressure blower (regenerative blower) installed on all models

Motor output: 0.55 kW to 11 kW - Noise level reduced by approximately 5 dB compared to previous models

- Optional inverter installation available

- I/O service terminals provided as standard on all models

- Built-in safety circuits

(high-reliability thermocouples used for all safety devices) - Custom configurations available

(remote control panels, airflow direction changes, special voltages, etc.) - Built-in timer adjustable in 1-minute increments

from 1 minute to 99 hours 59 minutes

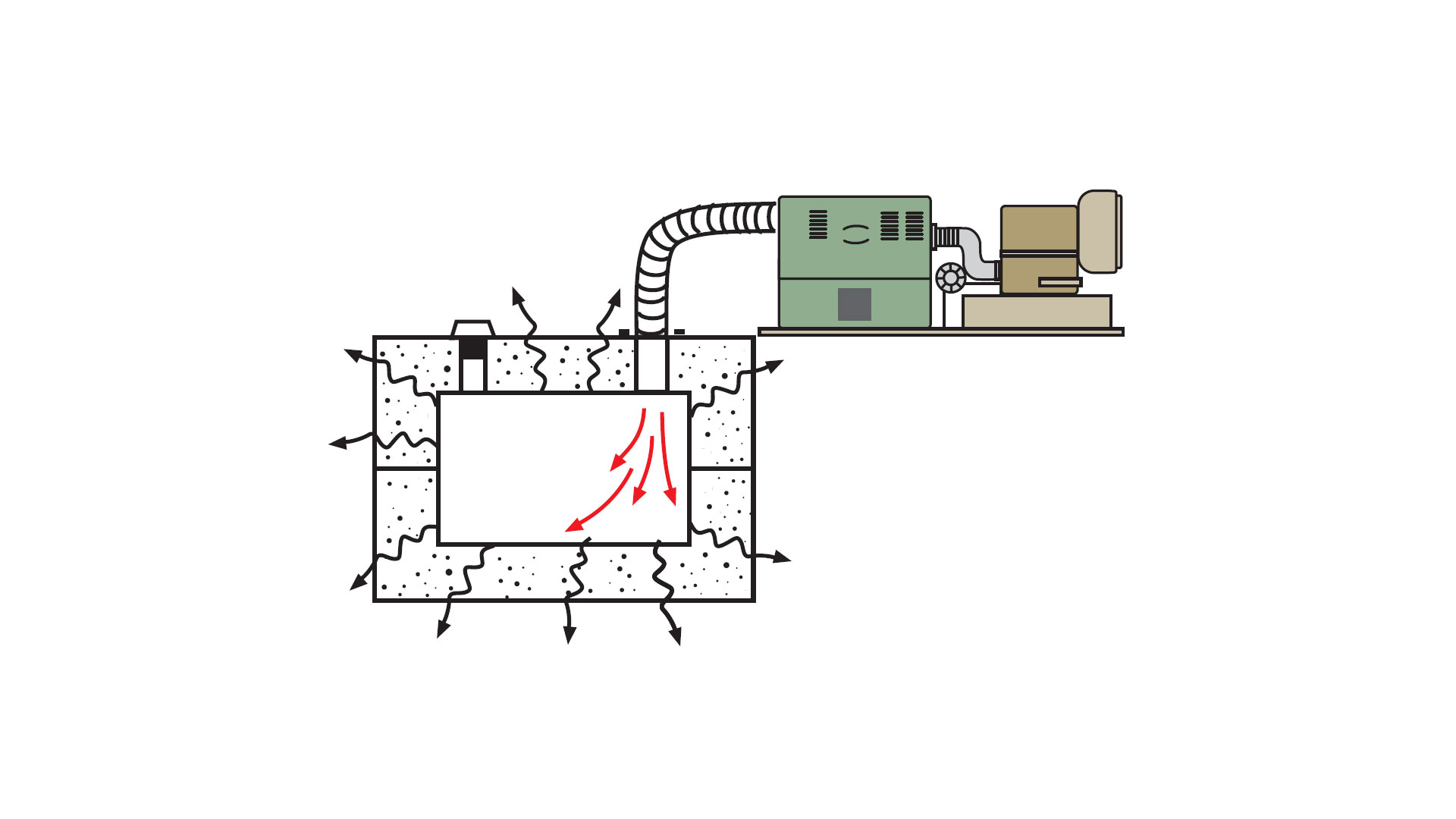

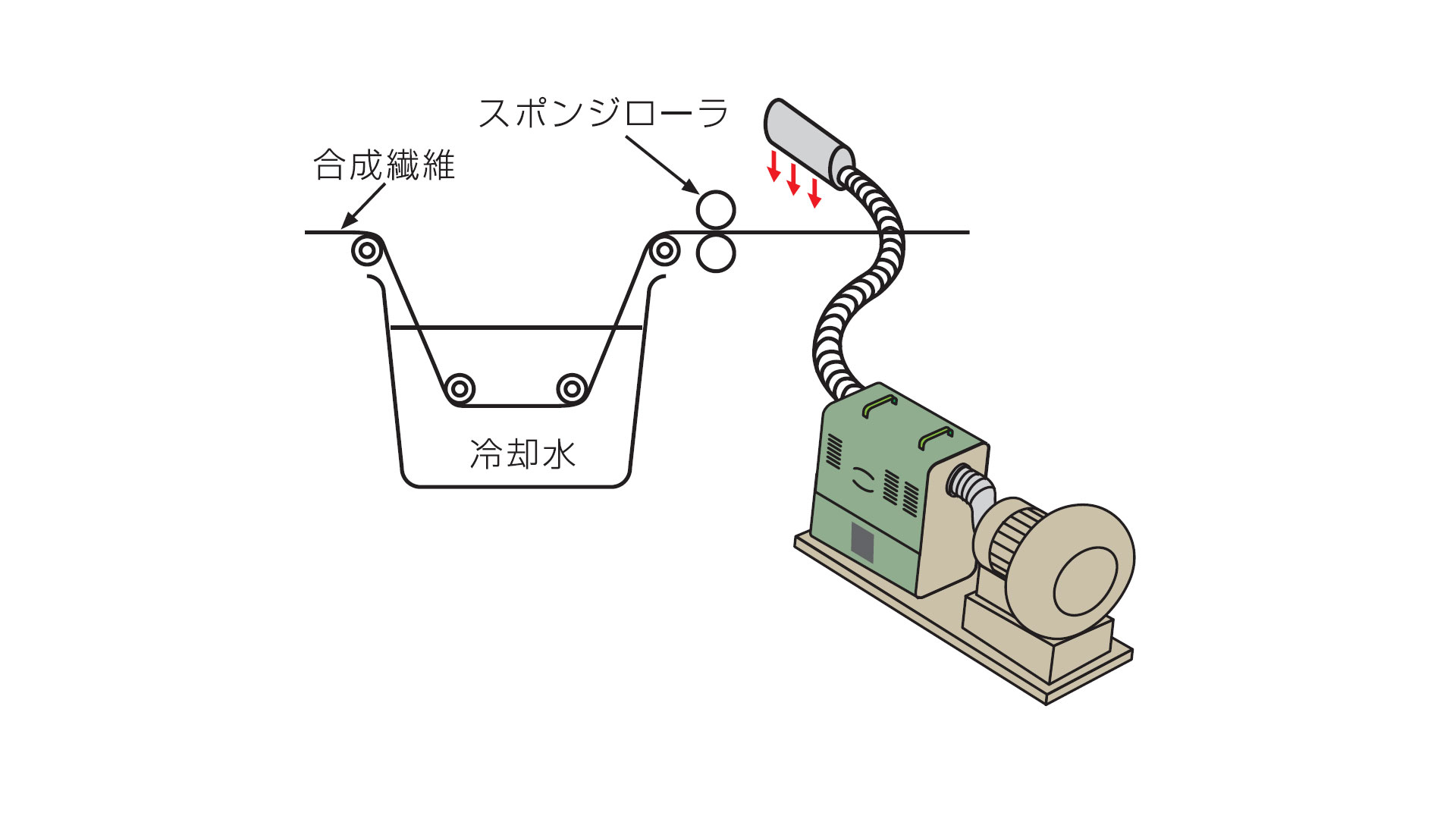

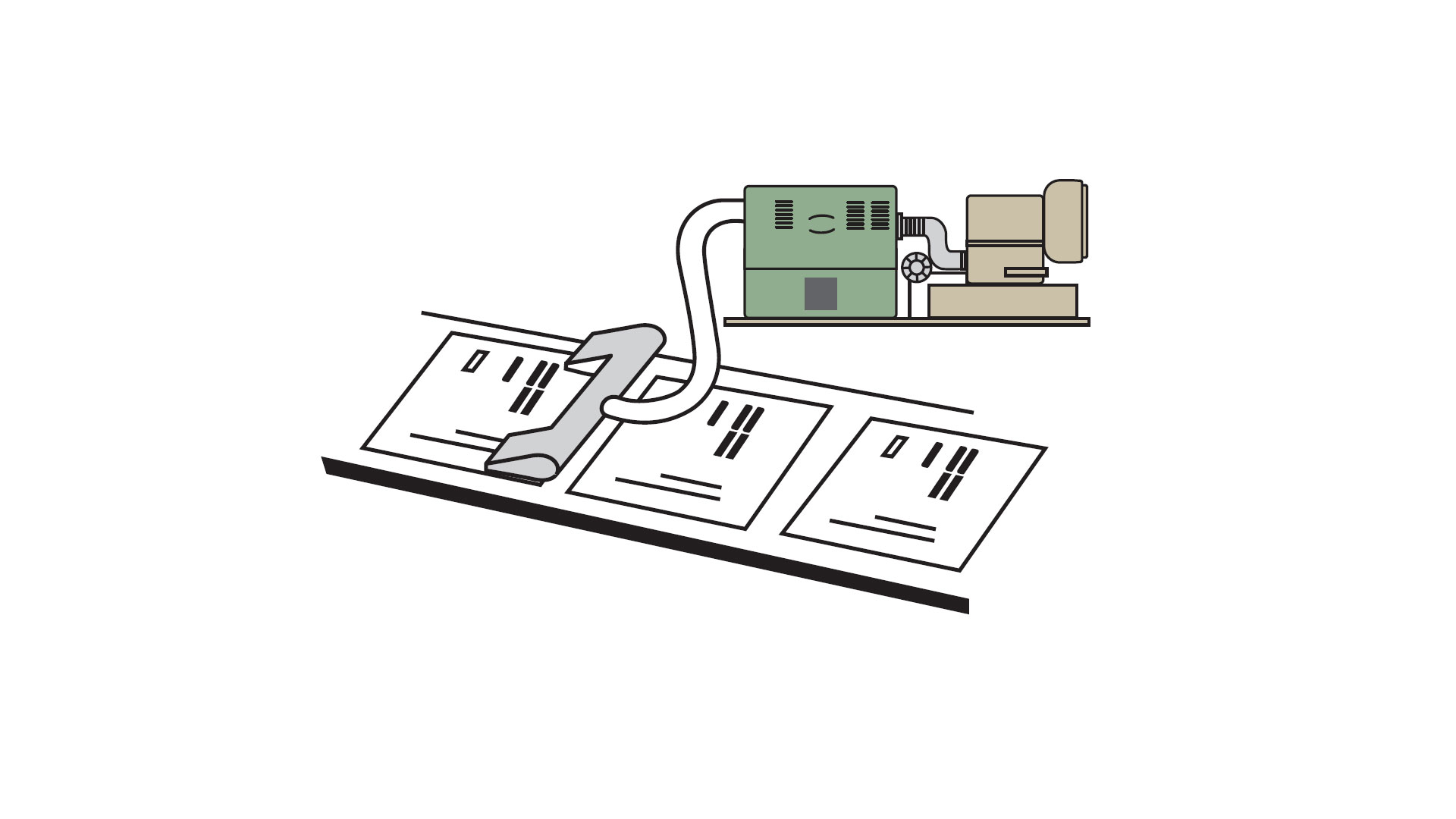

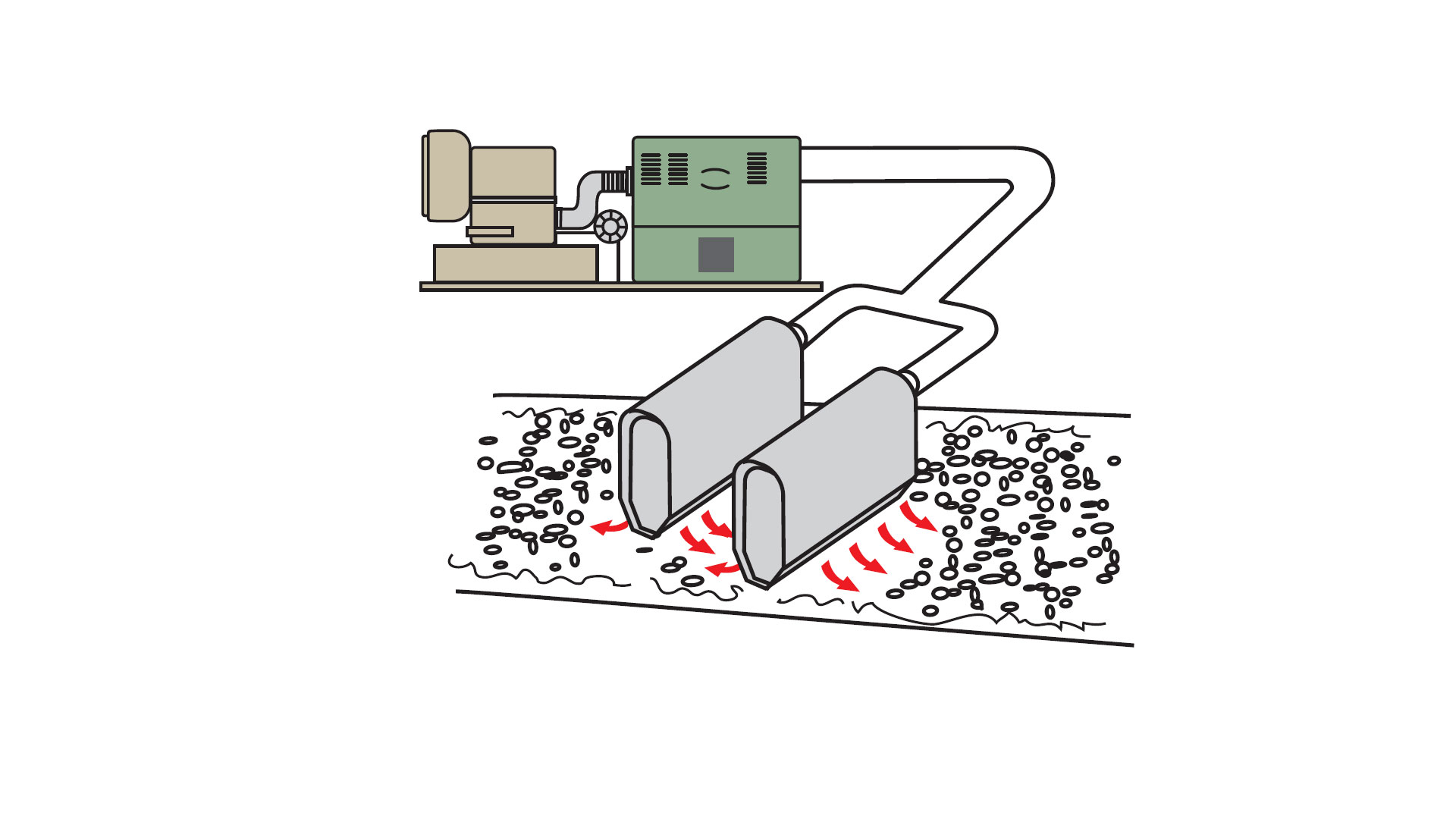

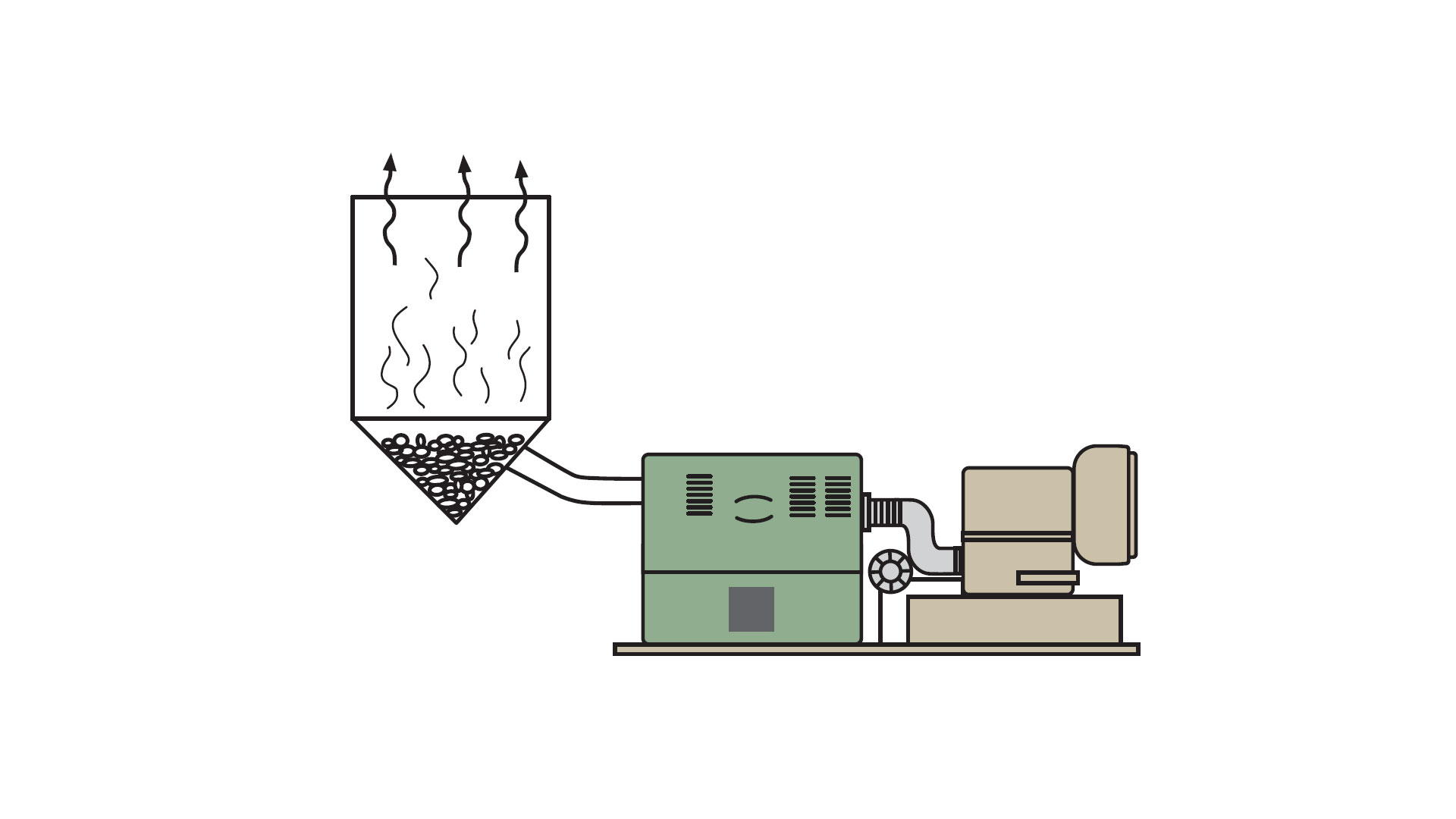

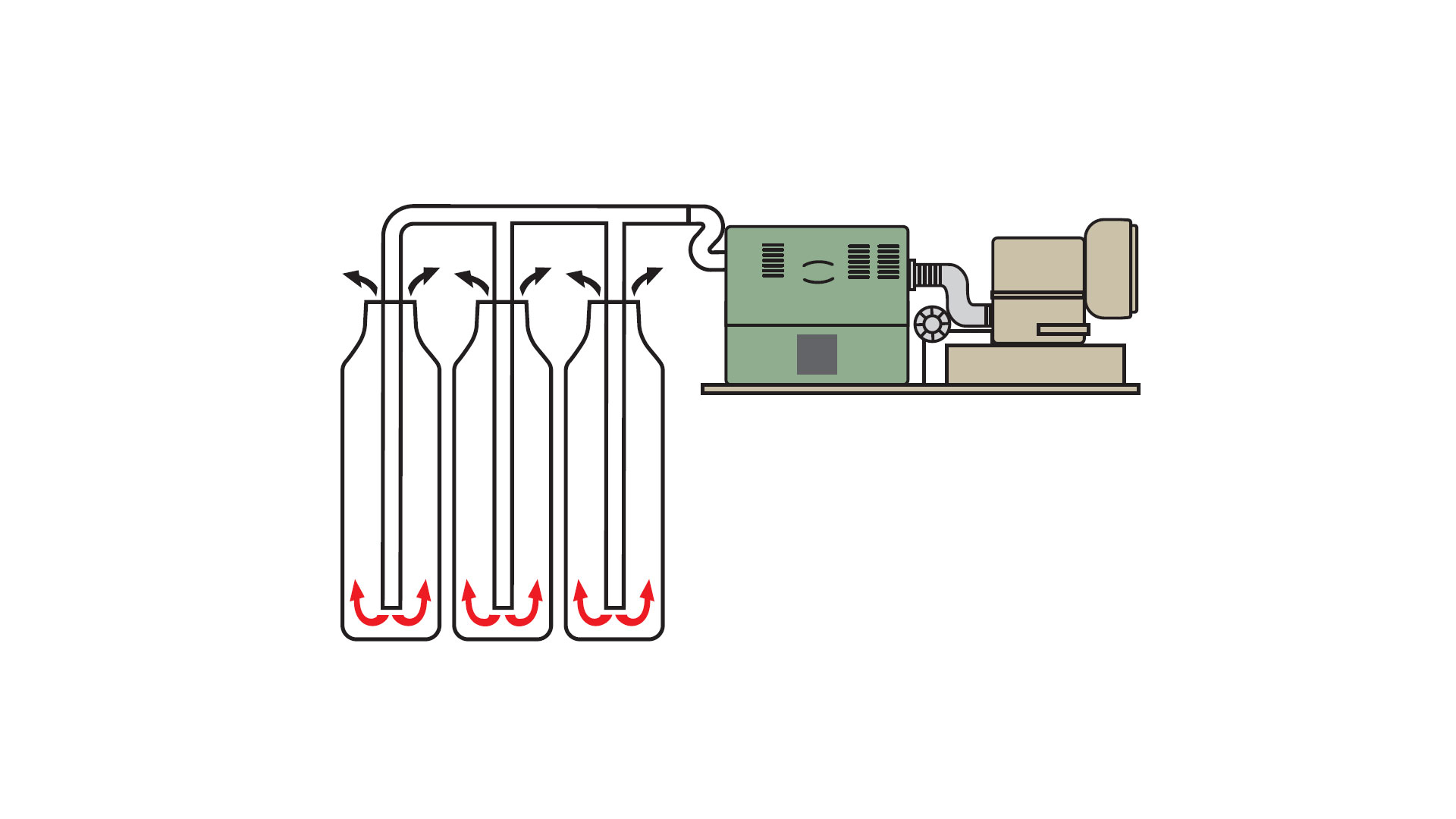

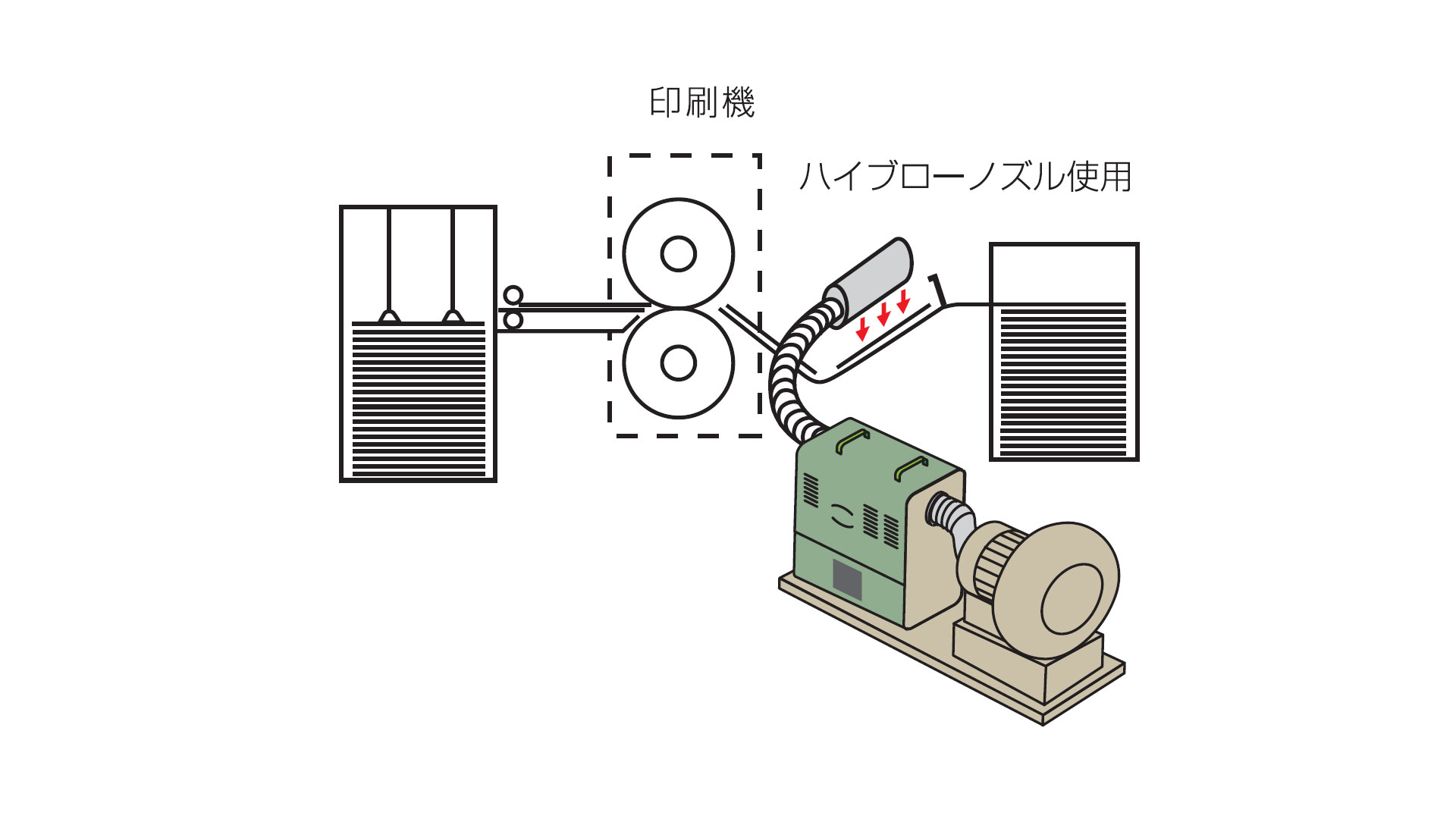

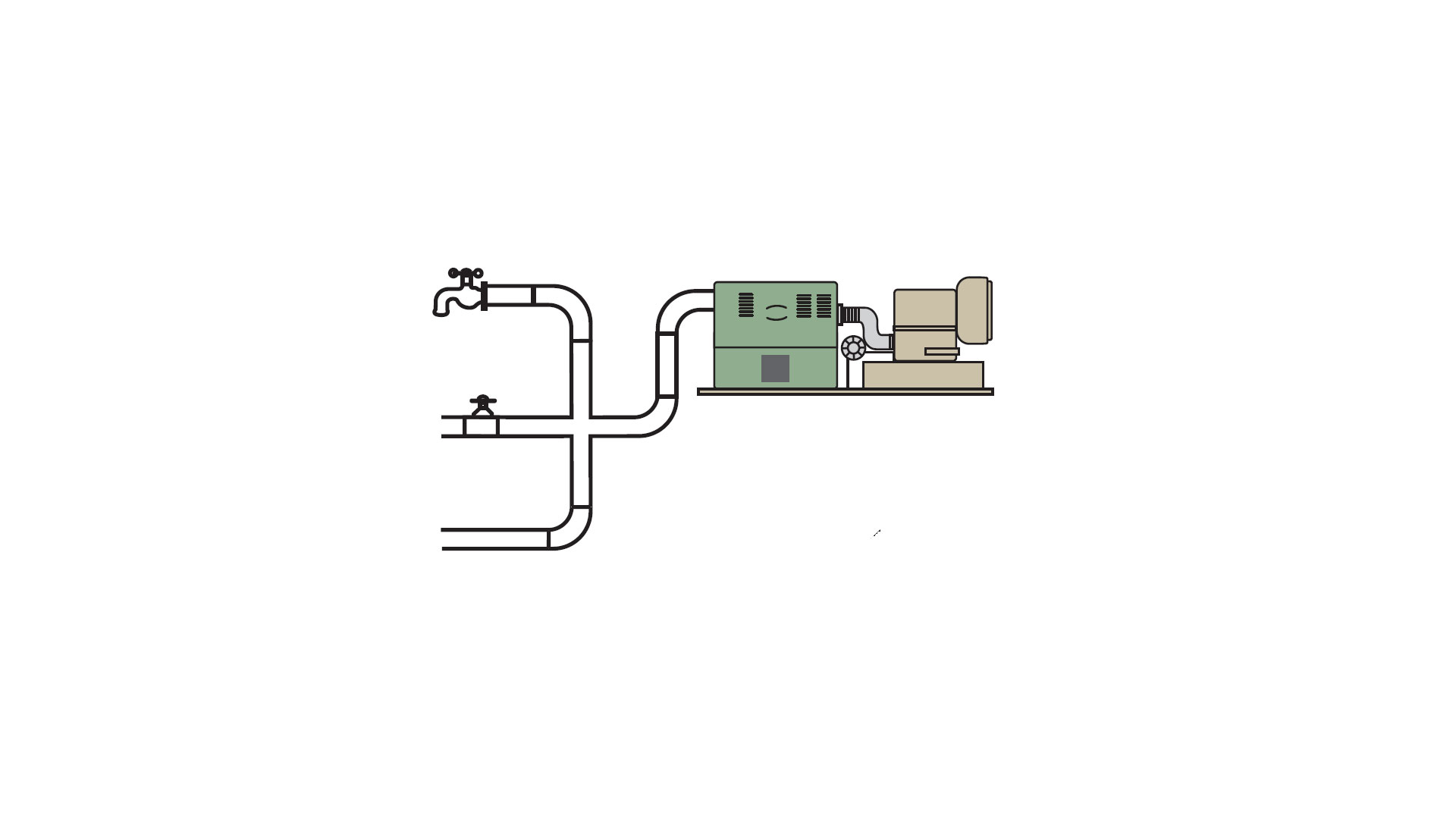

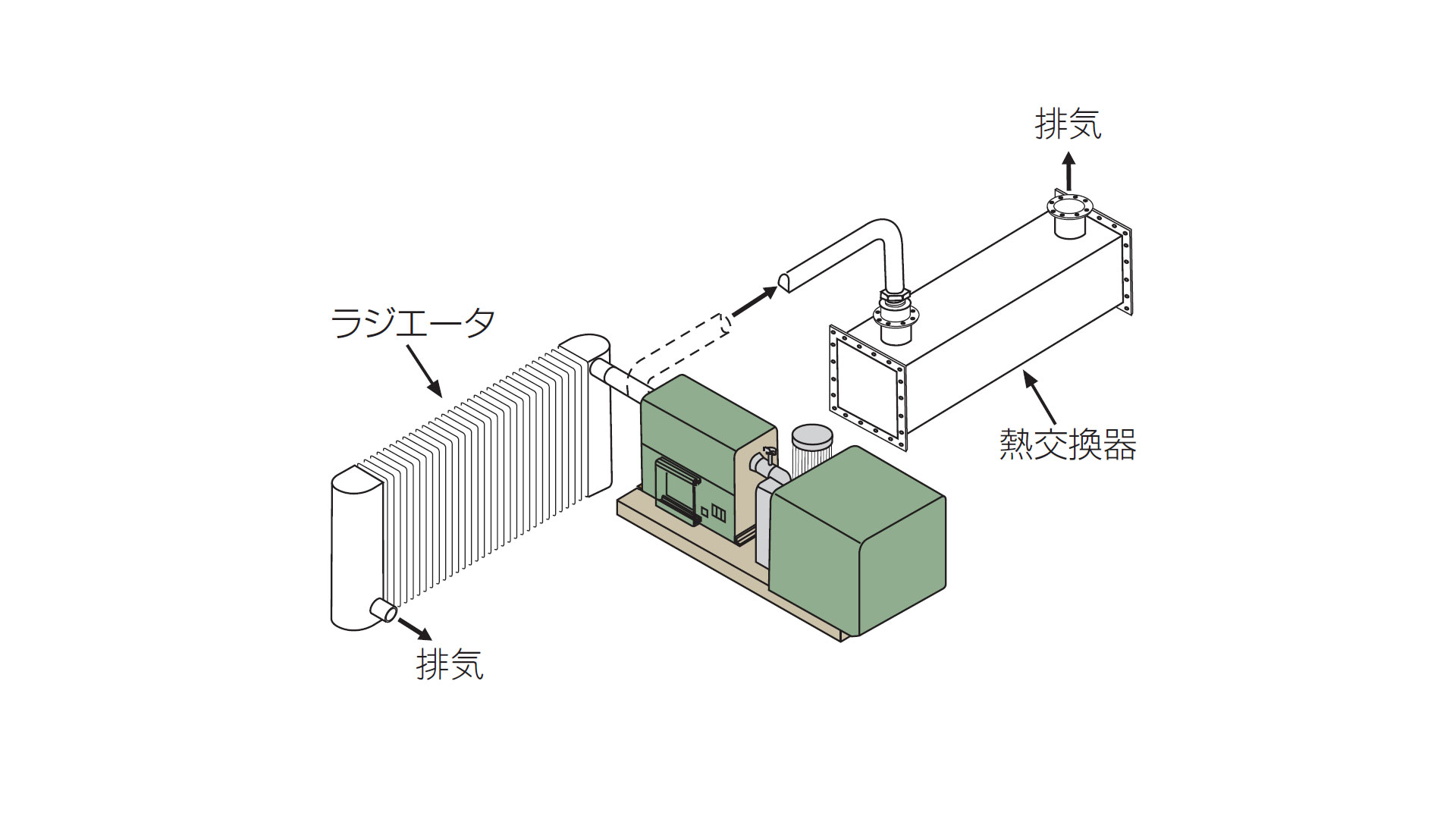

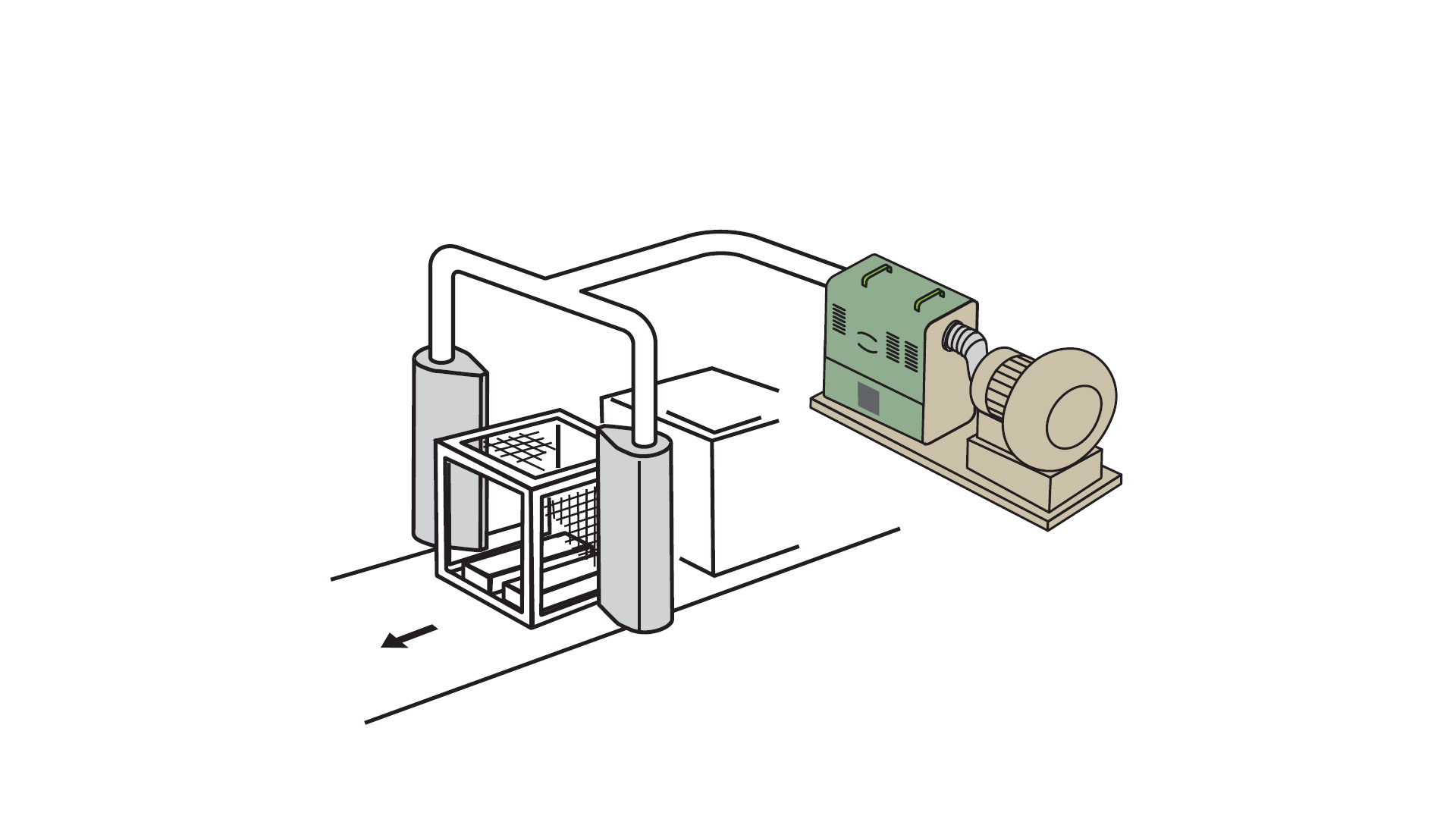

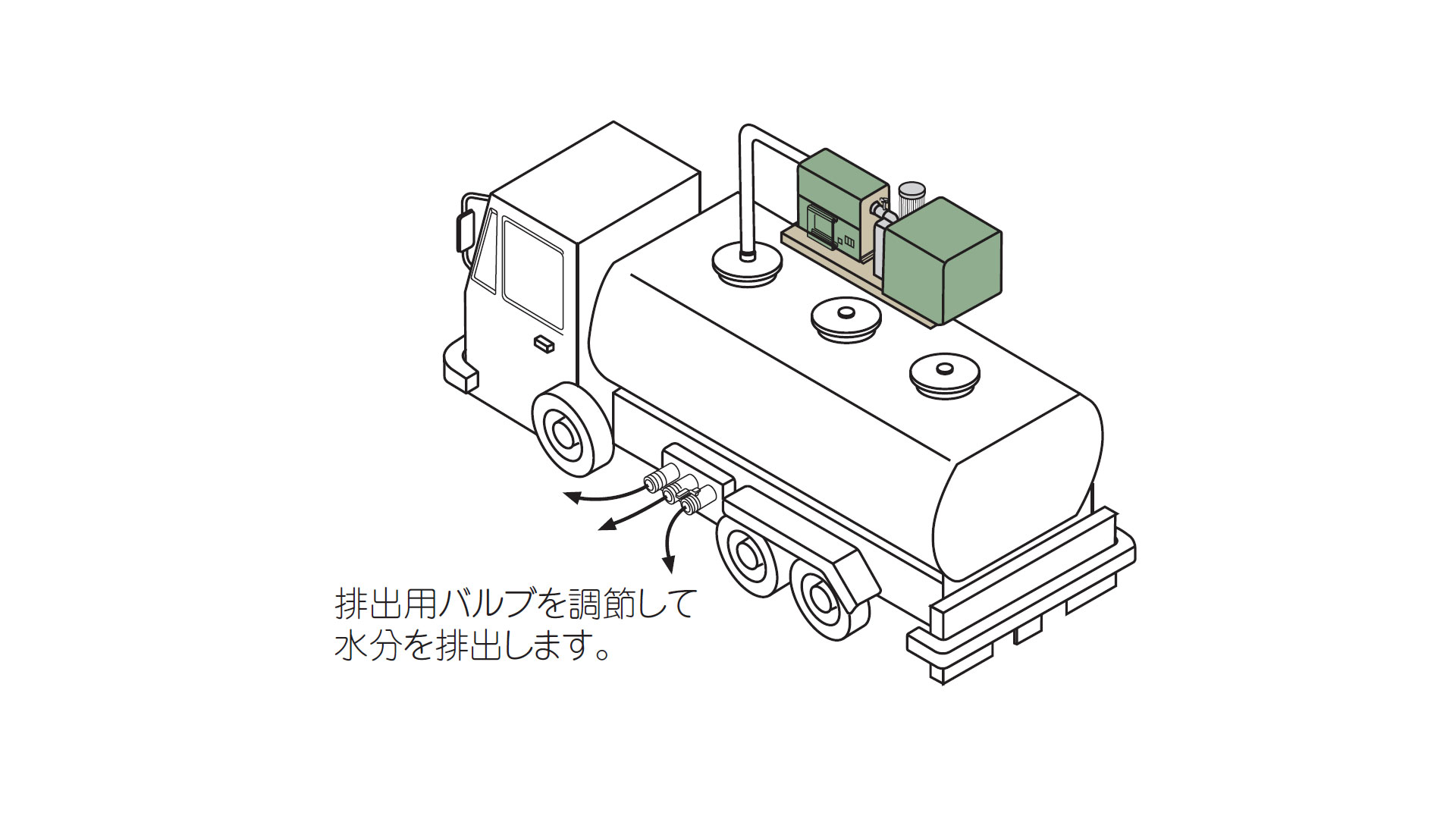

Typical Applications

Note: Some illustrations may contain Japanese text.

Our products can also be used for many other applications. Please feel free to contact us for further consultation.

Standard Specifications List

Note: Model numbers and power supply specifications vary depending on the voltage and frequency.

The compatible frequency differs by voltage specification.

Please specify the required voltage and frequency when placing your order.

| Model |

TSK-22H4 |

|

|---|---|---|

| Model Nos. | 3380-440-3C-X4-L | 3380-440-5C-X4-L |

| Power Supply |

3-phase 380 V / 415 V, 50 Hz |

|

| Heater Capacity | 3 kW | 5 kW |

| Max Outlet Air Temp. | 350 °C | |

| Max Inlet Air Temp. | 40 °C | |

| Max Air Volume | 1.9 / 2.2 m³/min | |

| Max Static Pressure | 10.1 / 13.8 kPa | |

|

|

|

| Model |

TSK-32H5 |

|---|---|

| Model No. | 3380-440-7.5C-X5-L |

| Power Supply |

3-phase 380 V / 415 V, 50 Hz |

| Heater Capacity | 7.5 kW |

| Max Outlet Air Temp. | 350 °C |

| Max Inlet Air Temp. | 40 °C |

| Max Air Volume | 2.9 / 3.3 m³/min |

| Max Static Pressure | 15.0 / 17.3 kPa |

|

|

| Model |

TSK-52H6 |

|---|---|

| Model No. | 3380-440-10C-X6-L |

| Power Supply |

3-phase 380 V / 415 V, 50 Hz |

| Heater Capacity | 10 kW |

| Max Outlet Air Temp. | 350 °C |

| Max Inlet Air Temp. | 40 °C |

| Max Air Volume | 4.1 / 4.9 m³/min |

| Max Static Pressure | 19.8 / 24.1 kPa |

|

|

| Model |

TSK-53H7 |

|---|---|

| Model No. | 3380-440-12C-X7-L |

| Power Supply |

3-phase 380 V / 415 V, 50 Hz |

| Heater Capacity | 12 kW |

| Max Outlet Air Temp. | 350 °C |

| Max Inlet Air Temp. | 40 °C |

| Max Air Volume | 5.4 / 6.1 m³/min |

| Max Static Pressure | 17.5 / 22.9 kPa |

|

|

| Model |

TSK-62H8 |

|---|---|

| Model No. | 3380-440-15C-X8-L |

| Power Supply |

3-phase 380 V / 415 V, 50 Hz |

| Heater Capacity | 15 kW |

| Max Outlet Air Temp. | 350 °C |

| Max Inlet Air Temp. | 40 °C |

| Max Air Volume | 8.0 / 9.3 m³/min |

| Max Static Pressure | 23.8 / 26.5 kPa |

|

|

| Model |

TSK72H9 |

|---|---|

| Model No. | 3380-440-20C-X9-L |

| Power Supply |

3-phase 380 V / 415 V, 50 Hz |

| Heater Capacity | 20 kW |

| Max Outlet Air Temp. | 350 °C |

| Max Inlet Air Temp. | 40 °C |

| Max Air Volume | 10.1 / 12.1 m³/min |

| Max Static Pressure | 24.8 / 25.1 kPa |

|

|

|

本体と離れた場所に設置・操作ができ、標準タイプには後付け可能 TSK-22H4・32H5:RCS-10MC TSK-52H6~72H9:RCT-10MC |