Kansai Electric Heat Corp.

Differences Between High-Efficiency Honeycomb Block Heaters and Sheathed Heaters

Overview

The TSK High-Efficiency Honeycomb Block Heater integrates heating wires into a low-pressure-loss honeycomb ceramic structure. This design allows air to pass evenly through both the inside and outside of the coiled heating wire, ensuring uniform and highly efficient heating.

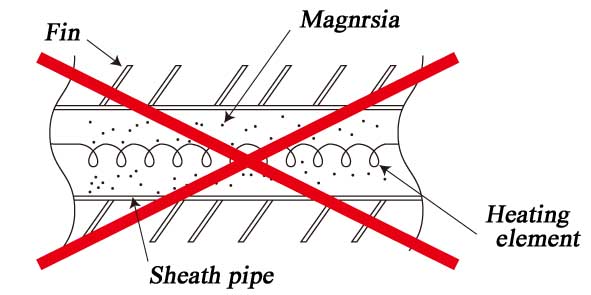

In contrast, a Sheathed Heater consists of a heating wire (heating element) encased in a metal sheath tube filled with an insulating material, typically magnesium oxide (magnesia).

|

High-Efficiency Honeycomb Block Heater |

Sheathed Heater |

|

|---|---|---|

| Thermal Efficiency | The heated air flows uniformly through both the inside and outside of the coiled heating wire, allowing nearly 100% of the heat to be converted into hot air. (P.A.T.) | Uses secondary heating, resulting in lower thermal efficiency and slower temperature rise. At high temperatures, the sheath pipe may deform, causing uneven heater spacing and reduced heat exchange performance. |

| Service Life | The watt density can be set low, which minimizes stress on the heating element and allows for semi-permanent operation without breakage, regardless of temperature. | High watt density increases the risk of wire breakage. Not suitable for high-temperature applications. Elevated internal temperatures shorten the heater’s lifespan. |

| Safety | Provide long-term safety due to sufficient insulation and spacing distances. | Insulation quality of the magnesia may degrade over time, leading to short circuits between the heating wire and the metal sheath. Corona or arc discharges may occur inside the insulating powder. Insulation performance decreases as the product ages. |

| Ease of Operation | No cooling operation is required. Temperature control is simple and allows for high-precision regulation. | Requires post-operation cooling. Skipping this step can cause failures such as wire breakage. |

Notes for Industrial Use

- TSK's honeycomb heaters are especially suitable for applications requiring stable high-temperature air with long operating life and low maintenance.

- Sheathed heaters may still be suitable for lower-temperature or non-continuous heating processes, but require more careful handling and maintenance.