Company ProfileCompany NameKansai Electric Heat Corp.Registered TrademarksRepresentativeSadayoshi TaketsunaCorporate Number1122001004388Qualified Invoice Issuer Registration Number (Japan Invoice System)T1122001004388Head Office5-4-18 Takaida-nishi, Higashiosaka-shi, Osaka 577-8566, JAPANTEL: +81-6-6785-6001FAX:+81-6-6785-6002Tokyo Branch Office2-4-4 Minami-Kamata, Ota-ku, Tokyo 144-0035, JAPANTEL:+81-3-5710-2001FAX:+81-3-5710-2005Second Factory5-4-11 Takaida-nishi, Higashiosaka-shi, Osaka 577-8566, JAPANBusiness Days Calendar2025 (Business Hours: 8:30–17:20)Banking PartnersMUFG Bank, Ltd., Tanimachi BranchPaymentInvoices closed at end of month, payment by bank transfer by end of next month (if the payment date is a holiday, transfer preceding business day)Sales methodDirect sales, mail-order sales, export/trade divisionOverseas AffiliatesOverseas distributorsDA CEI TRADE CO., LTD. (TAIWAN)3F, No.75, SEC 1, Hsin Tai Wu Rd., Hsichih, Taipei, TaiwanTEL: 02-8698-1111 FAX:02-8698-1000HOMEPAGE:https://da-cei.com/zh/home/E-Mail:sales@da-cei.comOverseas distributors Longxi TRADE CO., LTD. (CHINA)Room 912, No. 106 Zhongjiang Road, Putuo District, Shanghai, ChinaTEL: 021-5178-1228 FAX:021-5178-1229TEL: +86-137-6313-4010 (WeChat)HOMEPAGE:https://da-cei.com/zh/home/E-Mail:tinky@da-cei.cnOverseas distributorsHANSHIN TECH CO., LTD. (KOREA)#513, Mecajon EZEN APT Factory, Yangchon Industial Complex, Hakun-ri, Yangchon-Myeon,Gimpo-si, Kyeonggi-do, KoreaTEL :031-983-5424 FAX:031-983-5447HOMEPAGE:https://hanshintech.netE-Mail:hanshinleem@naver.comEstablishedIn 1931 as a manufacturer and seller of scientific instruments.94 years in business as of 2025.Company Name ChangedOn February 28, 2014, the company name was changed to “Kansai Electric Heat Corp.”Major Clients / IndustriesOver 11,000 companiesManufacturing (electrical equipment, mechanical parts, casting & forging, food, packaging, chemical products, medical devices, automobiles, shipbuilding), trading companies, import/export businesses, environmental sanitation industries, academic and research institutions (schools, laboratories), power plants, public corporations, government agencies, and other related fields.Industrial Property Rights66 registered designs64 utility models and patents (including applications in Japan and overseas)Production SystemComprehensive design (research on ceramics, airflow, and heat-resistant materials), manufacturing of high-temperature blowers, air-type heat exchangers, electric deodorizing equipment, dry exhaust-gas treatment systems for CVD equipment, resistance wire processing, insulating bushings, electronic circuit boards, control panels, airflow control devices, piping sheet-metal components, metalworking, full assembly and performance inspection, dynamic balance testing for rotating equipment— all manufacturing is conducted at our own plants in Japan.Heater Capacity ProducedHigh-temperature, high-pressure electric hot-air heaters ranging from 4,400 kW/h down to our smallest standard model of 350 W/h.Annual Manufacturing CapacityTotal heater production equivalent to 400,000 kW per year, plus sales of related components (piping materials, filters, blowers, etc.)Industry ClassificationManufacture of applied equipment such as AC motors and related devices. Member of the Excellent Pollution Control Promotion Council, Registration No. 0211.Business Purpose1. Development, design, manufacturing, and sales of applied equipment such as AC motors and heating devices.2. All business activities incidental or related to the above.Factory EquipmentHybrid drive benders, integrated process compact machines, AC servo bending machines, CAD/CAM programming systems, turret punch machines, die polishers, metal sliders, automatic programming devices, 24-hour automatic resistance-wire processing machines, automatic/semi-automatic welders, M60 hydraulic wrenches (MAX60), two NC laser cutters, two NC turret punch presses (with manipulators), NC tapping machines, lathes, large upright drilling machines, two 4-roll automatic bending machines, three dynamic balancers, shearing machines, automatic storage systems, laser markers, three spot welding machines, and other major sheet-metal and welding machinery (totaling 130 units).Overhead cranes (4 units), high-voltage testers, hydrostatic pressure testers, frequency converters, and 95 major assembly and measuring instruments.Particle counters, gas detectors, diamond saw machines, hot-air drying furnaces, three electric furnaces capable of 1200 °C, annealing furnaces, hot-air forming furnaces, castable drying furnaces, radiation thermometers, vibration testing machines, high-pressure washing systems, durability and environmental testing equipment (23 units total), mixing machines, videoscopes, fiberscopes, strobe tachometers, portable abnormal-vibration detectors for rotating machinery, 600 °C thermographic cameras, digital and analog optical pyrometers, multiple demonstration hot-air generators for sales, and 3-phase 440 V test-operation power supplies.Incoming power capacity: 450 kVA. Dedicated parking for materials procurement at headquarters.Employee Welfare FacilitiesBicycle parking, employee parking (motorcycles & cars), rooftop baseball pitching machine facility (fully fenced; also suitable for golf practice), baseball club, fishing club (company-owned boat), photography club, Kii-Tanabe recreation facility, employee dormitory at Tokyo Branch, etc.Table tennis area, game machines, electric massage chairs.Separate changing rooms for men and women, sanitary facilities on each floor.Gas heat-pump air conditioning throughout the building, large ventilation systems.Smoking rooms with forced-air ventilation isolated on each floor.Large indoor rest area and dining space equipped with microwaves, coffee makers, and water coolers.

400°C Specification / Low Pressure Loss & High Airflow Type

Hot Air Generator Available in Single-Phase 100V / 200V

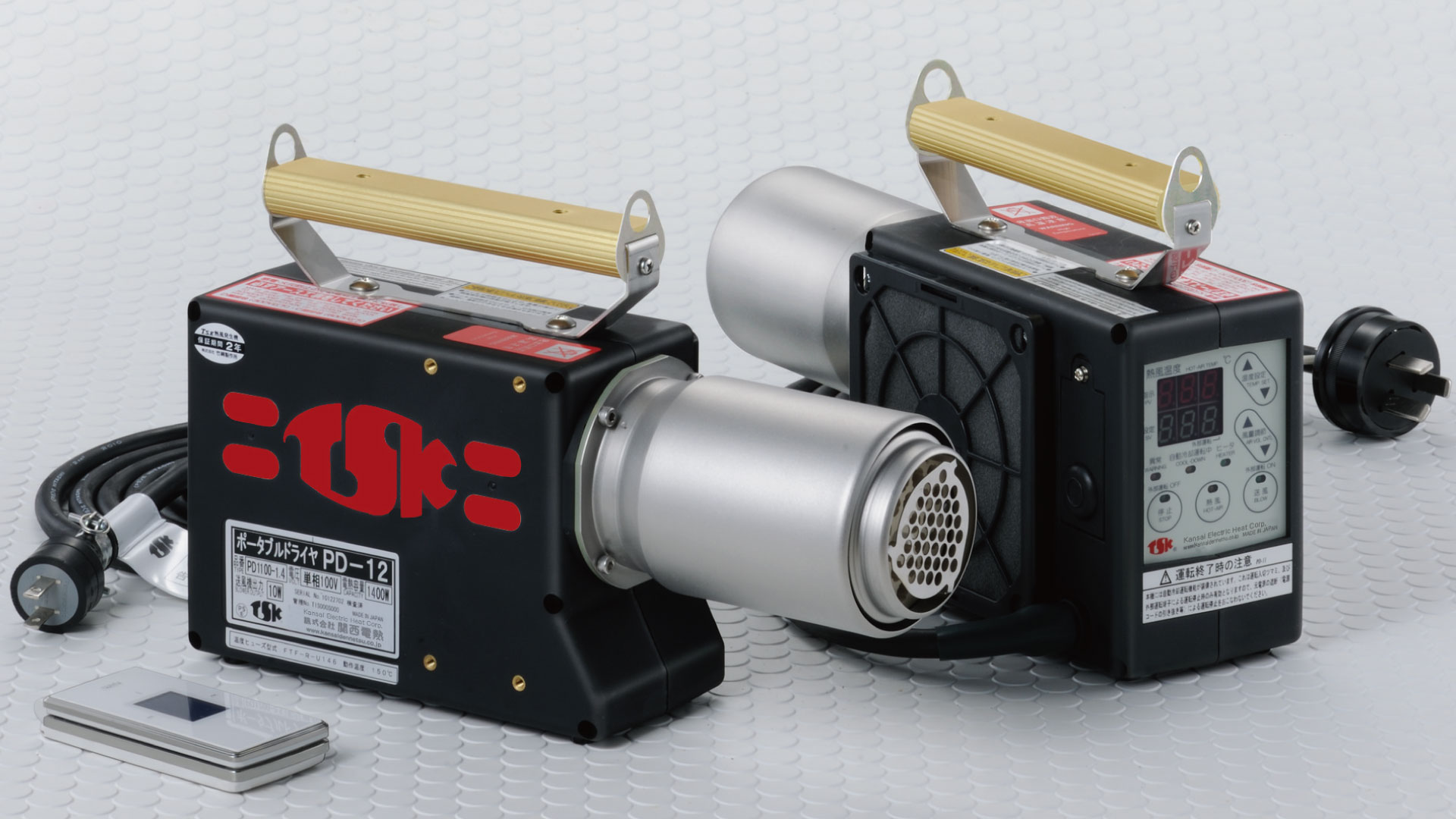

Mold Dryer Designed to Meet the Needs of Foundries

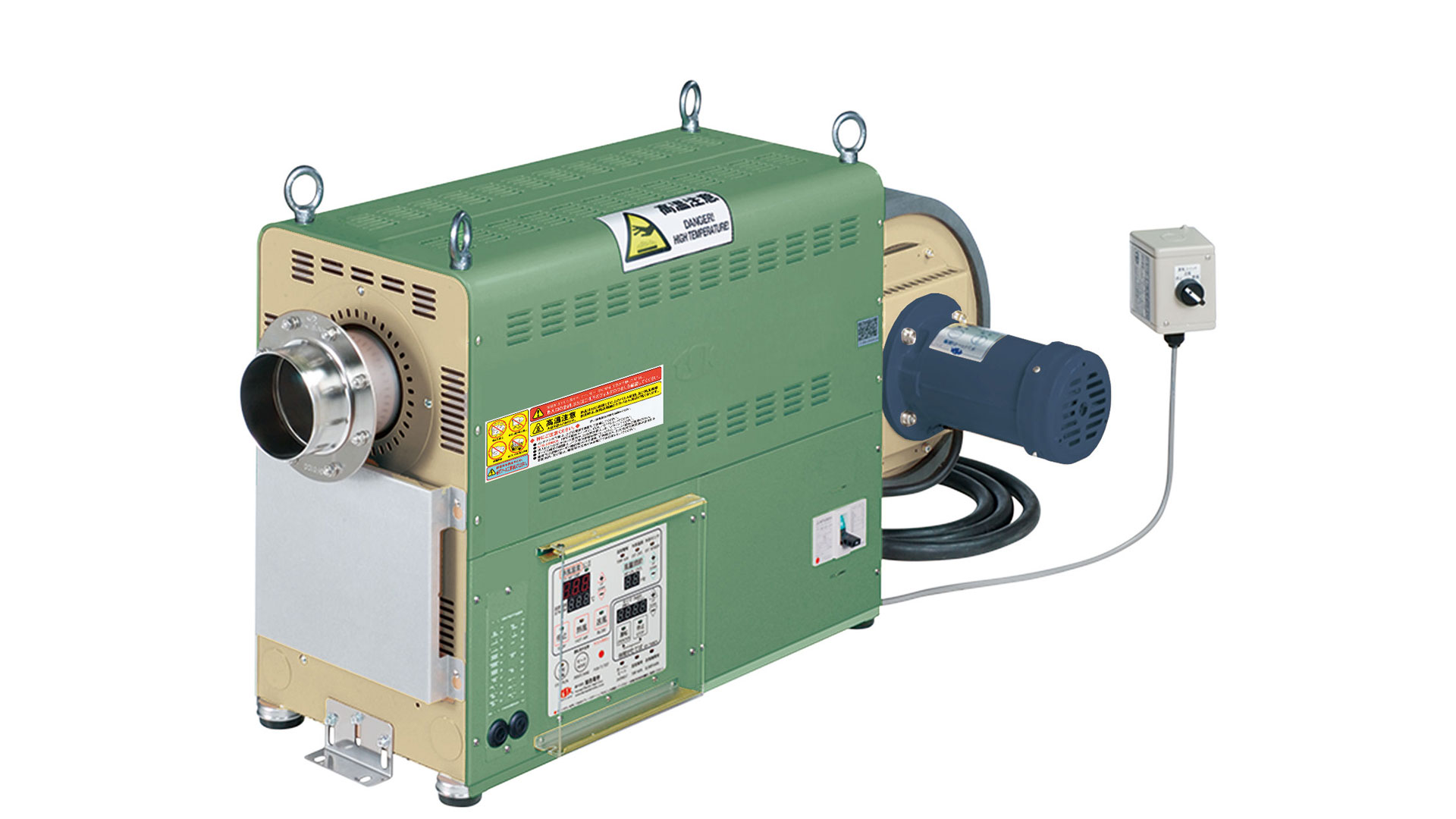

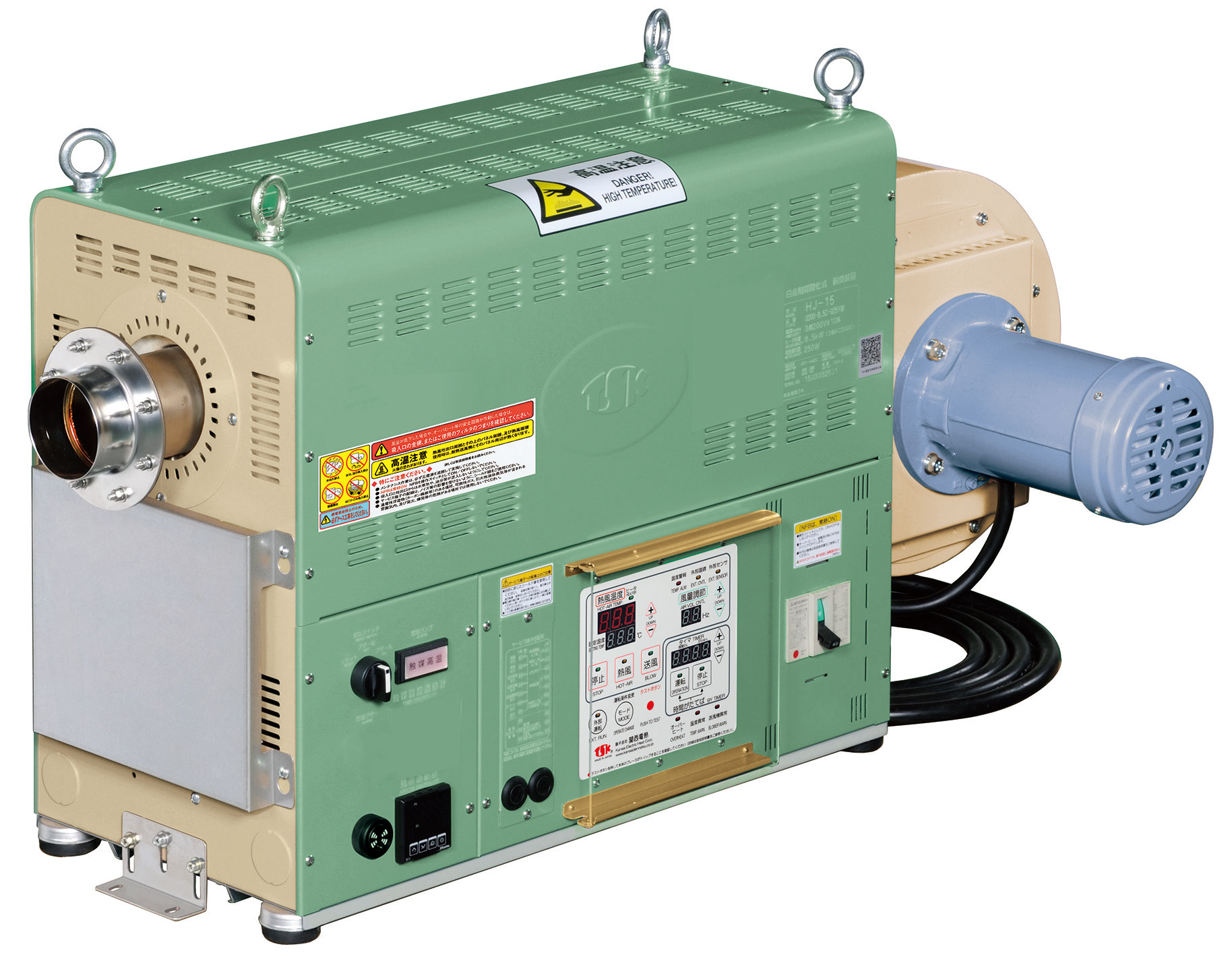

Electric Hot Air Generator – All-in-One Model with Full Functions

High-Temperature Hot Air Generator Capable of 500°C Output

Oxidation Deodorizing Heater with Built-in Platinum Catalyst

Flexible Configuration Options – Heater Unit Only or Without Control Panel

Equipped with a High-Pressure Blower – Ideal for Nozzles and Small-Diameter Piping

Medium-Pressure Fan Type with Hot Air Circulation Capability

Unique Model with High-Pressure Fan and Hot Air Circulation

800°C High-Temperature Hot Air – Ideal for High-Temperature Heating

Compact Design Capable of Easily Generating 800°C Hot Air

Heater Capable of Heating Blower Air up to 800°C

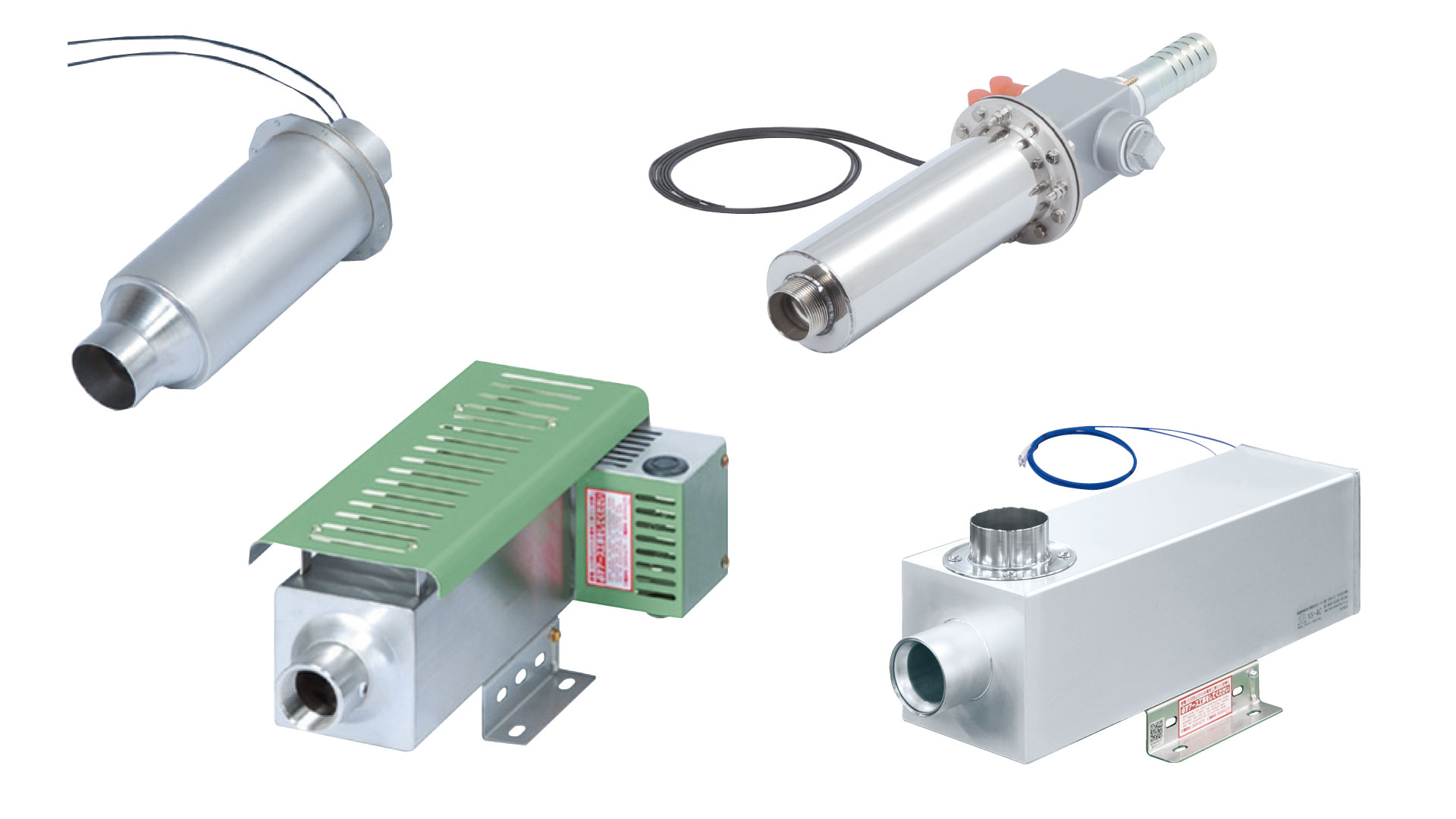

Slim Design Ideal for Pinpoint Heating

Extremely Low Pressure Loss – Ideal for Built-in Equipment Applications

Fan-Assisted Heater – Creates Ambient Temperatures Below 50°C

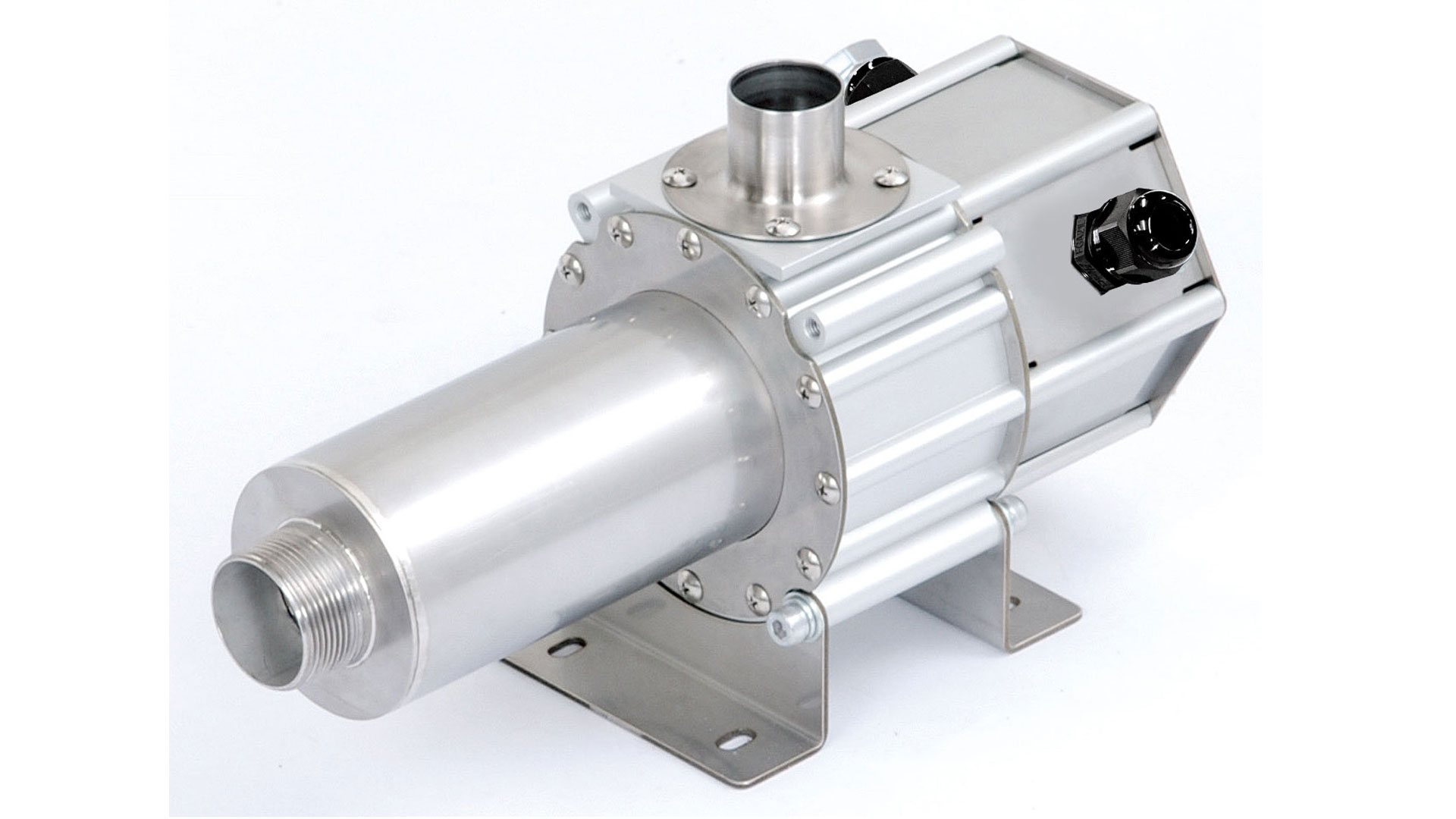

Compact Heater Designed According to Pressure Rating and Heater Capacity

Rugged and Safe Heater Designed for Construction Site Applications

Precision Slit Nozzle for Uniform and Accurate Air Discharge

Cylindrical Nozzle without Protrusions – Ideal for Close-Range Blowing

Compact and Lightweight Aluminum Nozzle

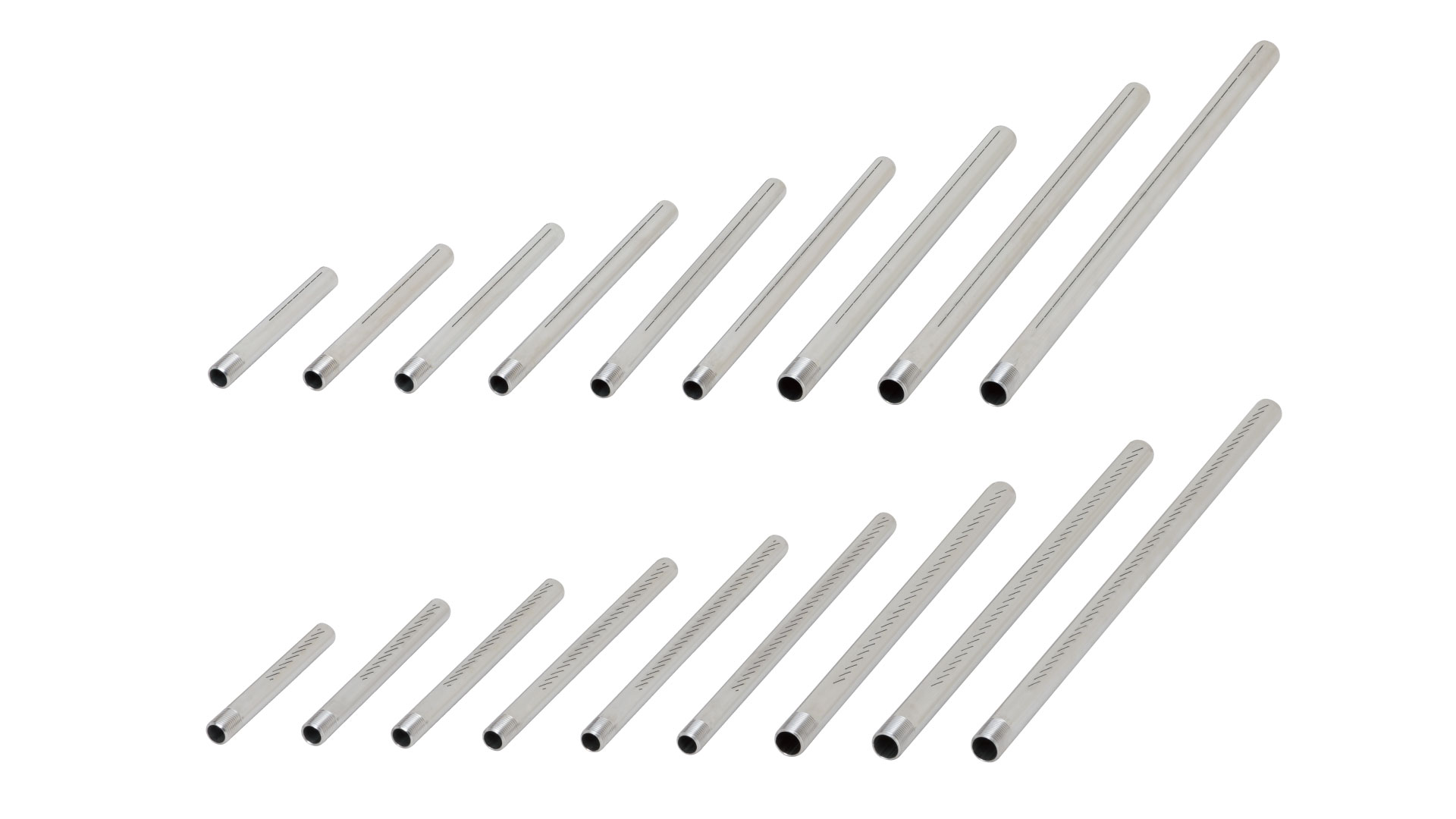

Stainless Steel Nozzle (Length 100–350 mm, Ø13) – Ideal for Finishing Applications

Low Pressure Loss, Lightweight, Long-Length Compatible Stainless Steel Nozzle

Heater Capable of Delivering Hot Air up to 650°C

Nozzle That Easily Creates High-Temperature Environments for Shrink Applications